Industry | Exploration the application of Atometrics in weld seam inspection With the development of modern industry, welding technology plays an increasingly important role in manufacturing. However, weld quality has always been a key factor restricting product quality and productivity. Weld inspection is an important part of quality management of welded structures, and is related to the success or failure of the entire structure or even project.

Below, Dr. Atometrics will introduce the exploration of Atometrics in the field of weld seam inspection and related application cases, if you also have the needs and problems on weld seam inspection, then please see the answer sheet presented by Atometrics for you!

Why need weld inspection?

The purpose of welding inspection, one is to ensure the integrity of the welded structure, safety and usability, and the other is to use the test results of the weld welding position control, weld line position control, welding pitch height control and weld tracking control.

Therefore, weld inspection is of great significance in ensuring product quality and improving production efficiency. Excellent quality management of welded structures can not only increase output efficiency, but also greatly reduce the rate of customer complaints to a certain extent, to ensure product quality and safety performance.

Weld Inspection Industry Application Areas

Weld testing involves a number of industry sectors, in the energy industry, the transmission of energy pipelines, equipment, welding results testing, etc. are required to weld testing to ensure the reliability of pipeline operation, to ensure the safety of oil and gas and other resources transmission, to protect the national economic interests from loss.

In the manufacturing industry, the industries that need weld testing include machinery manufacturing, automobile, bridge, construction, ship and so on. For example, in the field of automobile manufacturing, the quality of weld seam directly affects the safety performance of the vehicle; in shipbuilding, the quality of weld seam has an important impact on the structural strength and safety performance of the ship; in bridge engineering, the quality of weld seam of steel structure directly affects the safety and service life of the bridge.

Welding quality inspection is also indispensable for steel structure construction, boiler manufacturing and pipeline engineering in the construction industry. For example, in the steel structure project, the quality of the weld affects the safety, stability and mechanical properties of the material; boiler manufacturing project also needs weld inspection to ensure the structural stability of the metal parts, to ensure the safety of the boiler in the operation process.

Classification and advantages and disadvantages of weld inspection methods

1. Visual inspection (VT)

Advantages: easy to operate, no need for expensive equipment; can quickly check the appearance quality of the weld

Disadvantages: subject to the operator's experience, highly subjective; unable to detect defects inside the weld.

2. Magnetic particle testing (MT)

Advantages: can detect defects on the surface of the weld; easy to operate, requires less operator experience and skill;

Disadvantages: cannot detect defects inside the weld; requires higher surface treatment of the weld.

3. Penetration Testing (PT)

Advantages: non-destructive testing, will not cause damage to the test object; wide range of detection, applicable to metal, non-metal and composite materials; easy to operate, low requirements for operator experience and skills;

Disadvantages: the detection effect is affected by the penetrant, environmental conditions, the shape of the defects, and the surface roughness of the material.

4. Eddy current detection (ET)

Advantages: can detect weld defects; non-destructive testing, less impact on the quality of the weld;

Disadvantages: affected by the state of the weld surface, oxidation, dirt, etc. to affect the accuracy; affected by the detection distance, the distance is too far away may lead to inaccurate results; affected by the electrical conductivity of the material, the electrical conductivity of the test material has certain requirements.

5. Ultrasonic Testing (UT)

Advantages: can detect defects in the weld; non-destructive testing, less impact on the quality of the weld;

Disadvantages: higher requirements for the operator's skills; higher requirements for the cleanliness of the weld surface.

6. Radiation Testing (RT)

Advantages: can detect weld defects; non-destructive testing, less impact on the quality of the weld;

Disadvantages: higher cost of equipment; higher skill requirements for the operator; the operation process may produce radiation.

7. Line Laser Measuring Instrument Inspection

Advantages: can detect weld defects; non-destructive inspection, less impact on weld quality; high measurement accuracy, up to the micron level; can be measured in real time, providing real-time data support for weld quality inspection; automated inspection can be realized;

Disadvantages: the equipment requires a certain cost.

In summary, the line laser measurement instrument inspection encompasses all the advantages of other inspection methods, but also make up for the shortcomings of other inspection methods, therefore, in all walks of life in the weld inspection work, the line laser measurement instrument is more and more widely used.

Principle of Atometrics 3D Laser Profiler Sensor AR-7000 Series

Atometrics 3D Laser Profiler Sensor AR-7000 series is a non-contact measuring device based on laser technology, which utilizes a high-brightness, long-life light source to emit a laser line beam of a certain wavelength. When this laser beam irradiates the sample to be measured, reflected light is formed and only the light of the corresponding wavelength can pass through the ultra-high-definition light-transparent optical glass and be received by the instrument. The instrument receives the reflected optical signal, and after data processing to get the point cloud data of the sample, so as to realize the detection of the sample surface contour, three-dimensional morphology, flatness, weld quality and so on.

Atometrics AR7000 Series

The three major advantages of Atometrics 3D Laser Profiler Sensor AR-7000 series

1. Adopting 3840-point high-precision measurement, the repeatability accuracy is as high as 0.4 μm, which can finely present the 3D shape of the product, and dramatically improve the image quality and degree of refinement.

2. The new optical path design can realize the measurement without blind area, improve the integrity and accuracy of the detection results.

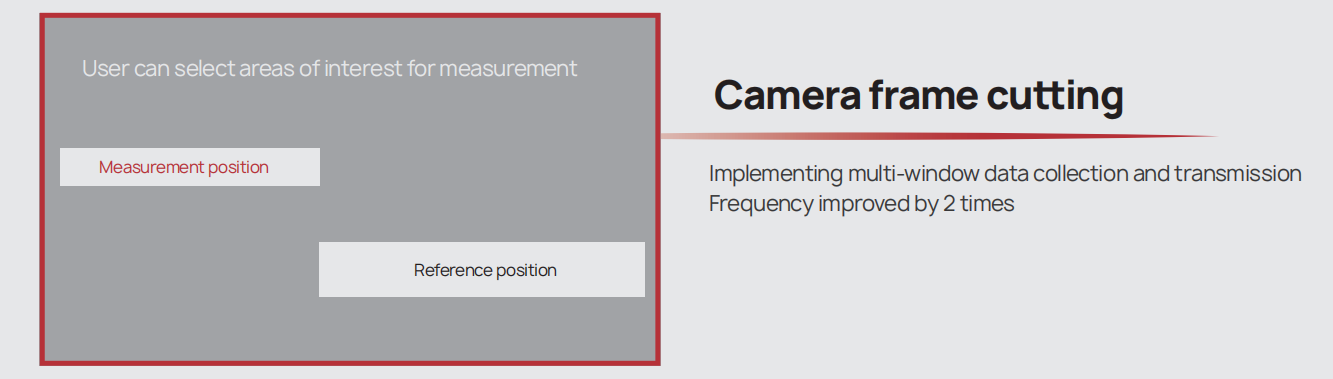

3. The user can customize the circle to select the area that needs to be measured for inspection, Atometrics 3D Laser Profiler Sensor AR-7000 series camera frame cutting, to achieve multi-window data acquisition and transmission, the frequency is increased by 2 times.

Application Cases of Atometrics 3D Laser Profiler Sensor AR-7000 Series

Case Background

A new energy technology enterprise focusing on lithium batteries and battery modules, BMS, energy storage batteries, in order to ensure the quality of the products, improve the safety performance of the products and reduce the rate of customer complaints, the enterprise would like to carry out the inspection of the side seam weld on the Busbar battery module, and the inspection items include weld breakage, gap, under the couch, blown holes, weld narrowness, bulge, and the amount of wrong edges, so as to detect and screen out the defective weld products.

Busbar battery module

In order to introduce cost-effective measuring equipment for weld seam inspection and to better improve product quality, the company turned to Atometrics, a domestically owned brand specializing in high-precision inspection.

Solution

1. Broken weld detection: It is required to determine NG when the length of broken weld part exceeds 1mm.

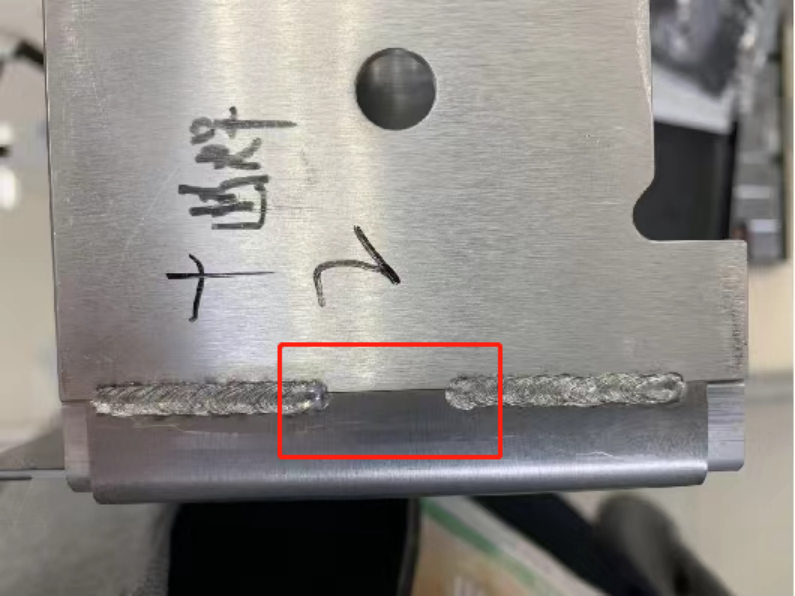

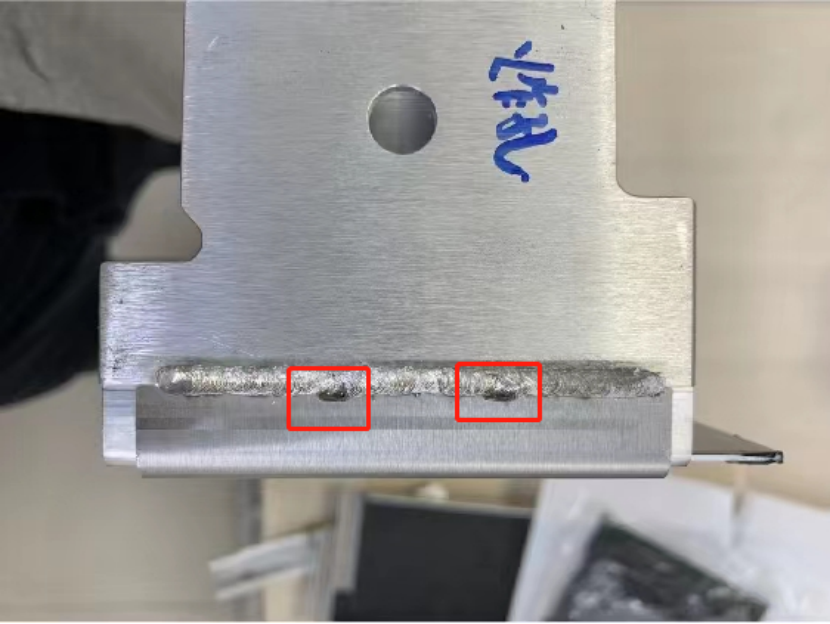

Picture of the broken part of the weld

Atometrics solution: using height point cloud map data for processing and continuous contouring tools for multi-location measurements of fracture differences.

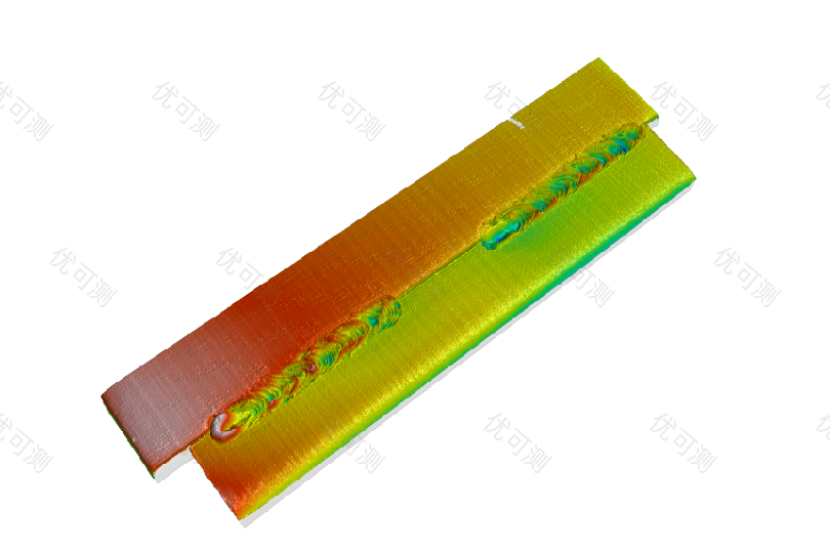

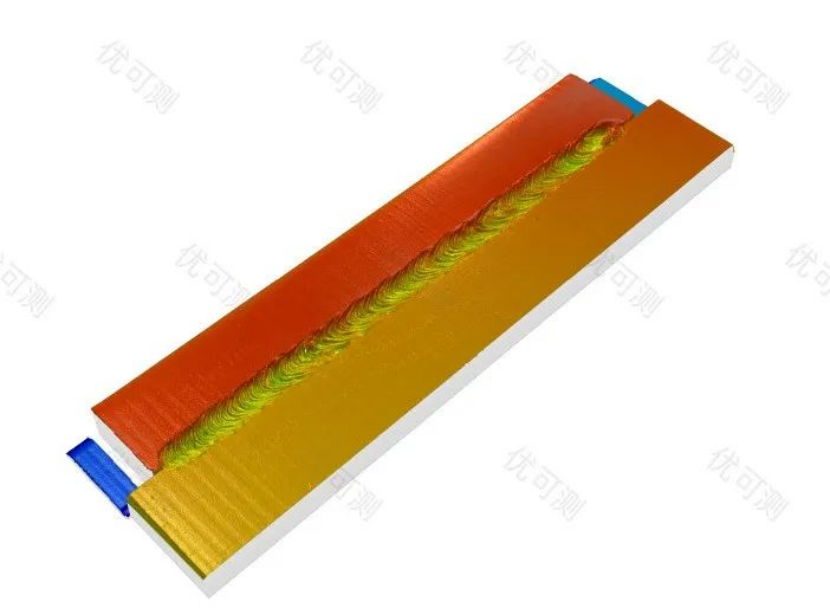

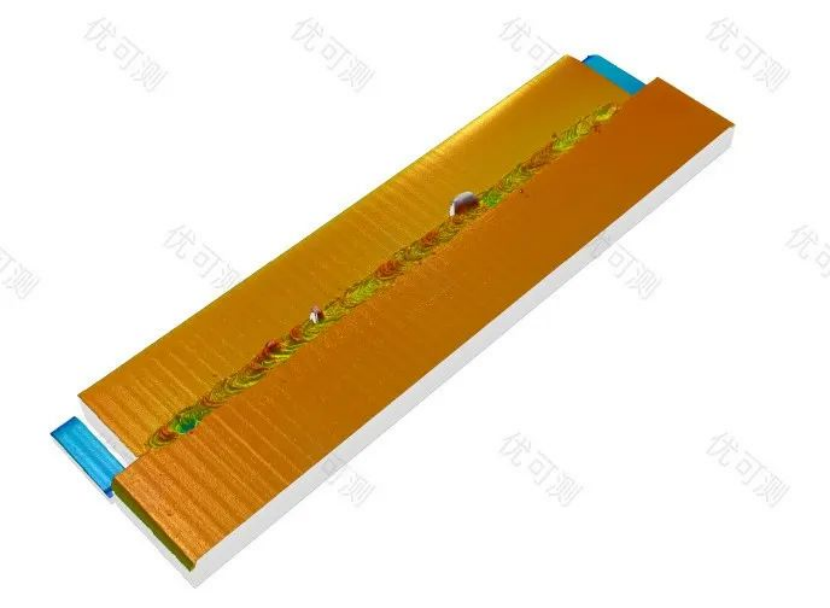

AR-7000 Scanning Weld Break Image

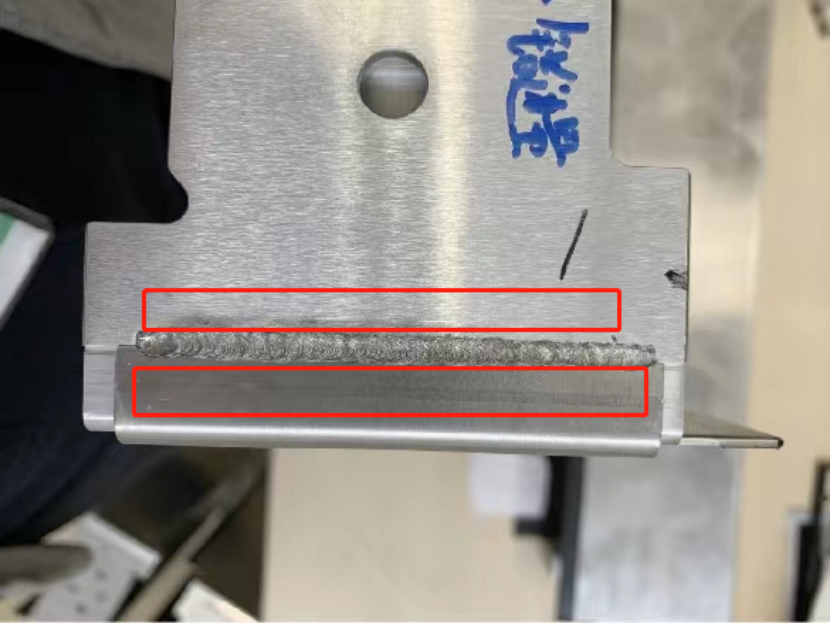

2. Couching test: It is required that when the length of the couching part exceeds 0.5mm and the depth exceeds 0.5mm, it will be judged as NG.

Welded seam under the couch part

Atometrics Solution: Using height images for processing, the under couch of the weld is measured by a height detection tool.

AR7000 Scanning image of couch part

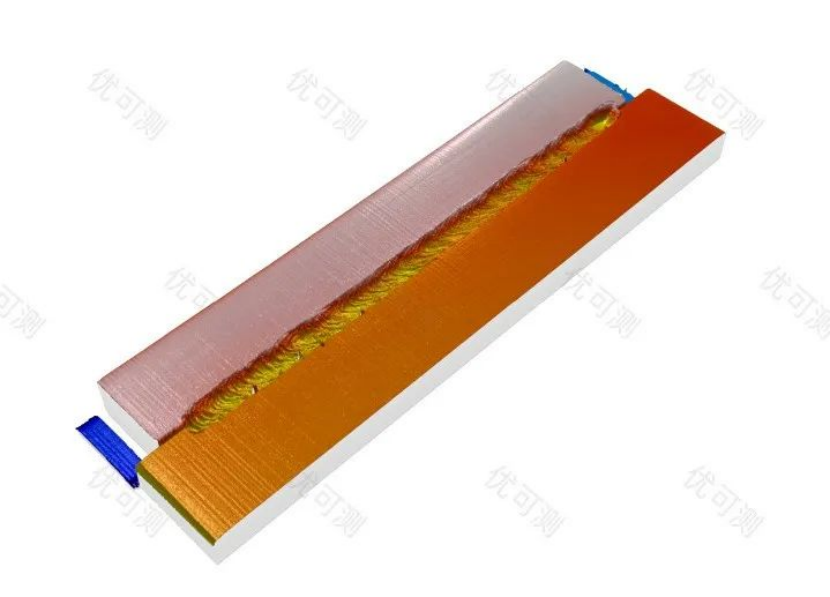

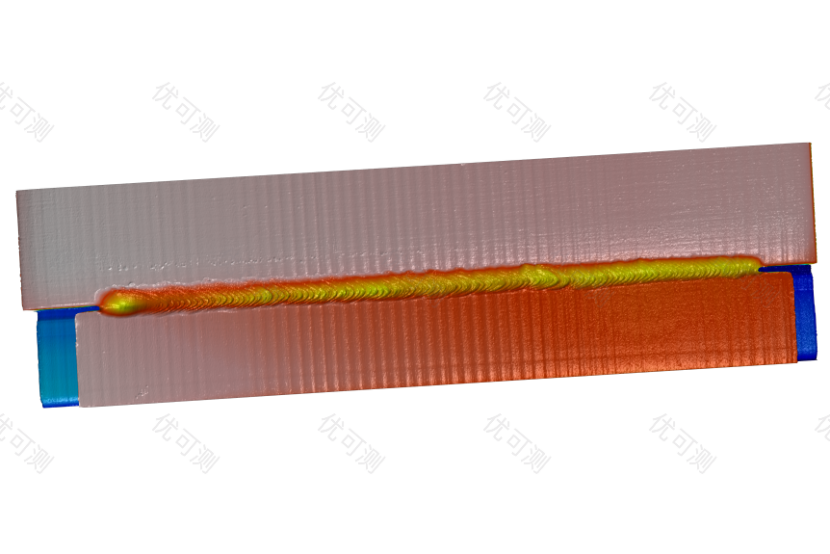

3. Blow-up point detection: It is required to determine NG when the diameter of the blow-up point exceeds 0.2mm.

Blow-up point

Atometrics solution: Processing using height images and grayscale images, measurement of weld blow-up points by depth and length detection tools.

AR7000 image of Blow-up point

4. The wrong side of the amount of segment difference detection: required when the height of the two ends of the value exceeds the standard value of 0.1mm or more, determine the NG.

Atometrics solution: use grayscale images for processing and use a width detection tool to measure the gap.

5. Gap width detection: Requirements when the gap width value exceeds the standard value of 0.1mm or more, determine the NG.

Gap width

Atometrics solution: use grayscale images for processing and use a width detection tool to measure the gap.

Gap width

6. The weld is too wide, raised detection: the requirements of the gap is too narrow, there is a raised product, determine the NG.

Weld seam bump

Atometrics solution: Processing using height and gray scale images, measurement of weld gaps, bumps by width and height detection tools

Weld seam Bump

Atometrics 3D Laser Profiler Sensor AR-7000 series has professional defect detection algorithms to meet the needs of all kinds of weld quality inspection, and can clearly and finely reflect the quality of weld seams. The operation screen can be customized to display images, data, statistics, etc.

Atometrics can be customized for customer's special measurement requirements, and also has certain script editing development capabilities, providing after-sales debugging and assisting in software development services.

For more details, application cases and product, please follow us or visit Atometrics official website!