Optical precision metrology is an interdisciplinary field based on optical principles and technologies, enabling high-precision measurements (at micrometer, nanometer, or even higher levels). It is widely applied in precision manufacturing, metrological science, materials engineering, biomedicine, and other fields. The core concepts of optical precision metrology are organized below across six dimensions: Basic Concepts, Core Technical Methods, Typical Measurement Objects, Key Instruments, Error and Calibration, and Application Fields.

I. Basic Concepts & Measurement Accuracy Terminology

Precision: The repeatability and consistency of measurement results (reflects the magnitude of random error).

Accuracy: The closeness of agreement between a measured value and a true value (reflects the magnitude of systematic error).

Resolution: The smallest physical quantity an instrument can distinguish (e.g., length resolution, time resolution).

Uncertainty: A parameter characterizing the dispersion of the measurement results (quantitatively describes the credible range of the measured value, composed of Type A evaluation (statistical methods) and Type B evaluation (non-statistical methods)).

Traceability: The property of a measurement result whereby it can be related to national/international standards through an unbroken chain of comparisons (ensures uniformity of quantities).

Fundamental Principles of Optical Measurement:

Geometrical Optics Principles: Based on ray propagation (rectilinear propagation, reflection/refraction laws), used for geometric quantity (length, angle) measurement (e.g., Laser Triangulation).

Physical Optics Principles: Based on the wave characteristics of light (interference, diffraction, polarization, scattering, spectroscopy), core to high-precision measurement (e.g., Interferometry, Diffractometry).

Coherence of Light: Temporal Coherence (Interference capability of light from the same source at different times, e.g., low coherence of white light used for profilometry). Spatial Coherence (Correlation of light emitted from different points of the source, e.g., high spatial coherence of laser light used for interferometry).

II. Core Technical Methods

1. Interferometry (Based on light interference phenomena)

Laser Interferometry: Utilizes the high coherence of lasers; measures length, displacement, etc., by detecting changes in interference fringes (e.g., single-frequency laser interferometers achieve nanometer-level length measurement accuracy; dual-frequency laser interferometers offer better anti-interference capability).

Fizeau Interferometry: Detects flatness, spherical curvature, etc., via interference between a plane/spherical reference wave and the wave reflected from the test surface (e.g., optical mirror surface form testing).

Michelson Interferometry: Beamsplit light interferes after reflection from two arms; used for micro-displacement, vibration measurement (accuracy reaching sub-nanometer level).

Twyman-Green Interferometry: Tests optical system aberrations (e.g., wavefront distortion of lenses).

White Light Interferometry (WLI) Profilometry: Utilizes the low coherence of white light; locates surface height via the peak position of interference fringes, achieving nanometer-level 3D surface topography measurement (e.g., semiconductor chip surface inspection).

2. Diffractometry (Based on light diffraction effects)

Grating Diffractometry: Utilizes periodic diffraction from gratings; measures length, angular displacement via fringe shift (e.g., grating rulers achieve micrometer-level length accuracy; circular gratings achieve arc-second level angular accuracy).

X-ray Diffractometry (XRD): Determines crystal structure by analyzing diffraction patterns of X-rays in crystals (e.g., material lattice constant measurement).

3. Imaging and Profilometry (Based on optical imaging)

Laser Triangulation: A laser beam illuminates the object, reflected light is imaged onto a detector via a lens, and distance is calculated from the spot position shift (used for fast 3D contour scanning, micrometer-level accuracy).

Focus Detection: Achieves nanometer-level Z-axis positioning by detecting the focus status of a light spot (e.g., astigmatic method, critical angle method), as used in the optical detection module of Atomic Force Microscopes.

Digital Holography: Records the interference hologram of object and reference waves; obtains 3D object topography via digital reconstruction (non-contact, robust).

Photogrammetry & Stereo Vision: Calculates 3D coordinates using parallax from images captured by multiple cameras (used for large component measurement, e.g., aircraft fuselage).

4. Spectrometry (Based on light-matter interaction)

Spectroscopic Analysis: Measures composition or physical quantities via absorption, emission, or scattering spectra (e.g., UV-Vis absorption spectroscopy for concentration, Infrared spectroscopy for molecular structure).

Laser-Induced Breakdown Spectroscopy (LIBS): Analyzes elemental composition via plasma emission spectra generated by laser ablation of material (real-time, in-situ measurement).

Raman Spectroscopy: Utilizes inelastic light scattering (Raman scattering) to obtain molecular vibration/rotation information, enabling material composition and structure analysis (e.g., biological tissue identification).

5. Polarimetry (Based on changes in light polarization state)

Stress Birefringence Measurement: Transparent materials under stress exhibit birefringence; stress magnitude and direction are reflected in the polarization interference fringe pattern (e.g., stress detection in glass, plastics).

Ellipsometry: Calculates film thickness, refractive index by measuring the elliptical polarization state (ellipticity, azimuth) of reflected light (sub-nanometer accuracy, used for semiconductor film inspection).

6. Laser Doppler Measurement (Based on Doppler effect)

Laser Doppler Velocimetry (LDV): Measures fluid velocity, solid surface velocity using the frequency shift (Doppler shift) of light scattered by moving particles (non-contact, mm/s level accuracy).

Laser Doppler Vibrometry: Determines vibration amplitude and frequency from the Doppler shift (e.g., micro-vibration detection in precision components).

7. Optical Fiber Sensing (Based on optical properties of fibers)

Fiber Bragg Grating (FBG) Sensors: Measure strain (microstrain level), temperature (0.1°C level) via the wavelength shift of the FBG reflection peak with strain/temperature (immune to EMI, suitable for harsh environments).

Fabry-Perot (F-P) Fiber Sensors: Utilize the interference effect within the F-P cavity in the fiber to measure displacement (nanometer level), pressure (Pascal level) (miniaturized, suitable for micro-structure measurement).

III. Typical Measurement Objects

Geometric Quantities: Length (nanometer to meter level), Angle (arc-second level), Flatness (nanometer level), Roughness (nanometer level), 3D Topography (micro/nano structures to large components).

Physical Quantities: Temperature (0.01°C level), Pressure (Pascal level), Strain (microstrain level), Vibration (nm/s level), Velocity (mm/s level), Flow Rate (µL/s level).

Optical Parameters: Refractive Index (10⁻⁴ accuracy), Transmittance/Reflectance (0.1% accuracy), Extinction Ratio (10⁻⁵ level), Dispersion (nm level wavelength resolution).

Composition & Structure: Material Elemental Composition (ppm level), Crystal Structure (Lattice constant 10⁻³ Å level), Film Composition (atomic layer thickness level).

IV. Key Instruments & Equipment

Interferometers: Laser Interferometer (length/displacement), Fizeau Interferometer (surface form), Twyman-Green Interferometer (aberration).

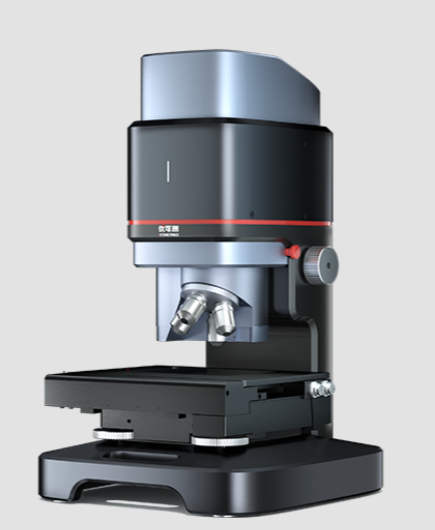

Profilometers: White Light Interferometer (micro-topography), Laser Scanning Profilometer (macro contour).

Spectrometers: Grating Spectrometer (0.1 nm wavelength resolution), Fourier Transform Spectrometer (high SNR).

Ellipsometers: Spectroscopic Ellipsometer (thin film parameters).

Laser Doppler Instruments: Laser Doppler Velocimeter (LDV), Laser Doppler Vibrometer.

Others: Laser Tracker (large-scale coordinates), Coordinate Measuring Machine (CMM with optical probe), Fiber Optic Sensing Systems.

V. Error Analysis & Calibration

Error Sources:

Systematic Errors: Instrument drift, environmental interference (e.g., ±0.1°C temperature change affects micrometer-level measurements), air flow/vibration (vibration isolation needed for nanometer-level measurements), optical misalignment.

Random Errors: Detector noise (photon noise, electronic noise), measurement repeatability fluctuations.

Gross Errors: Outliers caused by abnormal disturbances (e.g., electromagnetic pulses, mechanical shocks).

Traceable Calibration: Calibrate instruments against national standards (e.g., Krypton-86 wavelength standard) or standard artifacts (e.g., gauge blocks, standard gratings).

Comparison Calibration: Multiple instruments measure the same object; correct errors through consistency analysis.

Self-Calibration: Instruments have built-in reference modules (e.g., length self-calibration in laser interferometers).

VI. Application Fields

Precision Manufacturing: Semiconductor lithography alignment (nanometer level), Aerospace component dimensional inspection (micrometer level), Optical mirror surface machining (nanometer level).

Metrological Science: Length standards (laser wavelength), Angle standards (circular grating), Time/Frequency standards (optical atomic clocks).

Biomedicine: Cell 3D morphology (fluorescence imaging + digital holography), Blood flow velocity (Laser Doppler), Tissue composition (Raman spectroscopy).

Materials Science: Film thickness & stress (Ellipsometry), Composite material strain (FBG), High-temperature material temperature (Laser-Induced Fluorescence).

Environmental Monitoring: Atmospheric pollutant concentration (Differential Optical Absorption Spectroscopy), Water quality components (Raman spectroscopy).