Microfluidic chips, also known as Lab-on-a-Chip (LOC), represent a scientific technology characterized primarily by the manipulation of fluids within microscale spaces. This technology integrates or essentially consolidates fundamental operational units—such as sample preparation, reaction, separation, detection, cell culture, sorting, and lysis—involved in fields like chemistry and biology onto a chip of just a few square centimeters or smaller. Microbial channel formation networks enable controlled fluid flow throughout the system, a technology of actualizing the functionalities of diverse laboratories in conventional chemistry, biology, materials science, optics, and more.

Currently, microfluidic chips are primarily applied in three domains: analytical diagnostics, screening/synthesis, and organ-on-a-chip technologies. In analytical diagnostics, microfluidic chips serve as platforms requiring minimal sample volume, rapid analysis, and high sensitivity, demonstrating immense potential in Point-of-Care Testing (POCT).

Enhancing Microfluidic Chip Performance

Demands Precise Surface Topography Control

A renowned Shanghai-based microfluidic chip brand sought to elevate product performance and quality by precisely managing reaction efficiency, reagent mixing uniformity, and fluid flow rates within its chips. This necessitated strict control over surface roughness, microchannel height, and width to meet diverse client requirements.

To achieve this objective, engineers urgently required higher-precision, more efficient inspection tools to address this challenge. A lead engineer stated, "Previously, we measured microchannel height via cross-sectioning and optical microscopy—results were inaccurate, severely compromising product performance control!"

White Light Interferometry Measures Surface Topography:

Multiple Metrics Impact Chip Performance

After extensive evaluation, the brand selected the Atometrics White Light Interferometer for parameter control. Compared to alternatives, Atometrics’s interferometer offers superior measurement accuracy, enhanced hardware and software support, and operates at >2x the speed of comparable devices. Atometrics’s professional technical team also provides effective technical support for future automated laboratory integration.

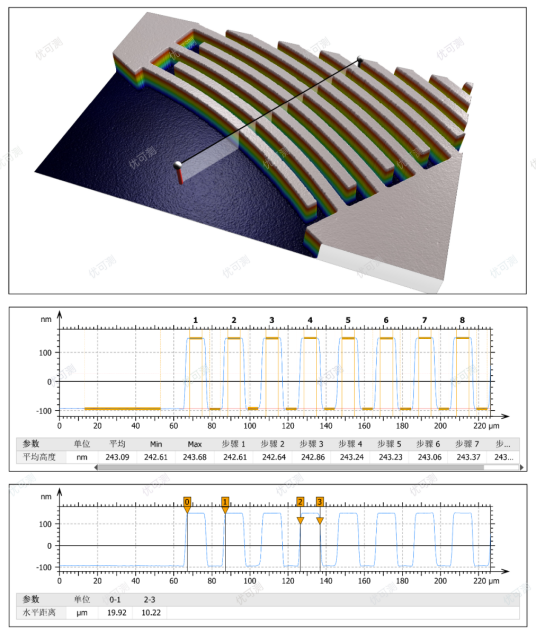

Finishing post-deployment and testing a trial period, Atometrics engineers identified that precise quantitative control of the surface roughness, height, and width of microfluidic chips significantly influences the flow rate of reaction reagents, reaction rate, and the completeness of the reaction.

Imaged by Atometrics AM-Series White Light Interferometer

Imaged by Atometrics AM-Series White Light Interferometer

Specific chips demand unique height/width specifications (such as: droplet chips determine microsphere size; organ-on-a-chip dimensions govern passage of specific cells/tissues).

Imaged by Atometrics AM-Series White Light Interferometer

Welcome to visit Atometrics website and follow us! Atometrics engineers will prioritize designing your optimal inspection solution!