3D printing, also known as "additive manufacturing," is a type of rapid prototyping technology. It is an advanced manufacturing technique that builds objects layer by layer using powdered plastics, metals, or other materials, based on digital model files. With continuous technological development and innovation, 3D printing technology has become a crucial tool in modern manufacturing.

I. Principles of 3D Printing Technology

The principle of 3D printing is quite simple. It slices a digital model into numerous thin layers and then prints these layers sequentially to construct the object. This layer-by-layer approach enables 3D printing technology to manufacture complex shapes and structures that are difficult or impossible to achieve with traditional manufacturing methods. Using 3D printing, we can produce a wide variety of objects, including parts, models, prototypes, medical devices, aerospace components, and more. This technology has found widespread application in fields such as automotive manufacturing, aerospace, biomedical engineering, and artistic design.

II. Development Opportunities for 3D Printing Technology

1. Material Innovation:

With ongoing research, development, and refinement of materials, the variety of materials usable in 3D printing continues to expand. Beyond traditional plastics, metals, and ceramics, new materials like biomaterials and composites are being applied, offering more choices across various industries.

2. Industrial Manufacturing:

As technology advances and costs decrease, the application of 3D printing in industrial manufacturing will become increasingly widespread. This technology can enhance production efficiency, reduce costs, and enable the realization of more complex product designs and manufacturing processes.

3. Biomedical:

3D printing technology holds vast application prospects in the medical and healthcare sectors. Using this technology, doctors can create personalized medical devices, prosthetics, and biomaterials for patients, lowering treatment costs while improving treatment efficacy and patient quality of life.

4. Defense and Aerospace:

3D printing technology finds excellent application scenarios in defense and aerospace fields. Examples include manufacturing lightweight aerospace structural components, producing the heat shield base for spacecraft like the Shenzhou capsule, and deploying mobile 3D printing units for on-site repair work in field operations.

5. Personalized Customization:

Modern society emphasizes personalization and differentiation. 3D printing technology is well-suited to meet the demand for personalized customization. Whether for consumer goods or industrial products, 3D printing allows for production tailored to individual needs, providing more personalized products and services.

III. Precision Measurement Requirements in the 3D Printing Field

Pre-Printing Measurement: Before 3D printing, it is necessary to measure the dimensions, 3D topography, etc., of the original design model to verify if the final product will meet performance and quality requirements. At this stage, optical scanners, such as the Atometrics 3D Line Laser Scanner AR Series, can be used to measure the model's 3D data for subsequent printing operations.

In-Process Monitoring: During the 3D printing process, real-time monitoring of product dimensional changes, shape deviations, layer height (in powder-based systems), or resin coating height (in SLA), and print platform displacement is sometimes required. Displacement sensors like the Atometrics Spectral Confocal Displacement Sensor AP Series can be integrated into the 3D printing equipment to acquire real-time dimensional information of the printed product or displacement distances of materials and the platform. This allows for the detection of deviations. If deviations occur, printing parameters can be promptly calibrated and adjusted to ensure the final object's dimensions, topography, and other parameters meet the target specifications.

Post-Printing Inspection: After 3D printing is complete, it is essential to inspect whether parameters like the printed product's dimensions, shape, surface roughness, and flatness meet design and quality requirements. At this stage, White Light Interferometers (WLI) driven by piezoelectric ceramics can be used to perform precision measurements of surface roughness and microscopic 3D topography, ensuring product quality compliance.

Below are case studies of Atometrics precision measurement instruments and sensors applied in the 3D printing field.

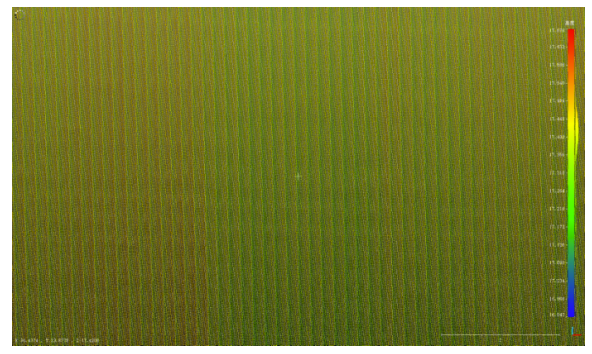

(1) Atometrics 3D Line Laser Scanner AR-7000 Series Inspecting a 3D Printed Plastic Cube Sample:

Since 3D printing builds objects layer by layer, it can introduce characteristic layer lines. This specific plastic cube sample had strict flatness requirements, necessitating 3D topographic analysis of the layer lines and precise flatness measurement.

Flatness = 154.364 μm

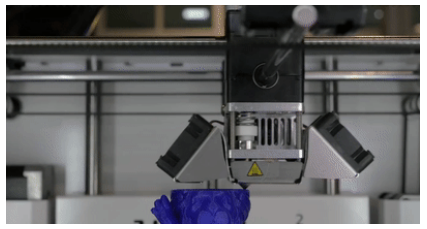

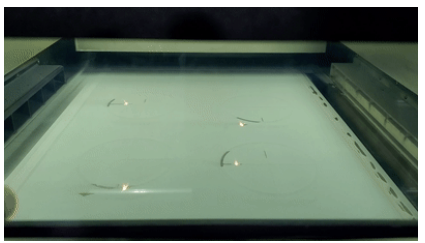

(2) Atometrics Spectral Confocal Displacement Sensor AP-5000 Series Integrated with a Liquid 3D Printer (SLA Process):

Stereolithography (SLA), an advanced additive manufacturing process, is primarily used in the prototyping stage for design validation. During liquid 3D printing, resin is coated layer by layer. After each layer is applied, a laser cures the photosensitive resin before the next layer is coated. Following each layer's curing, the build platform lowers to make space for subsequent printing. Precise control of the resin coating height is critical as laser curing is highly sensitive to the distance between the laser and the resin surface. The Atometrics Spectral Confocal Displacement Sensor AP Series is integrated into the printer to monitor the liquid resin coating height in real-time.

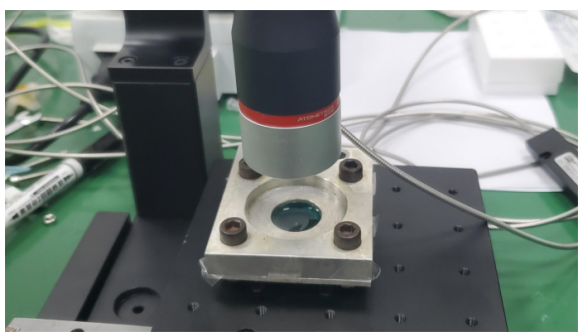

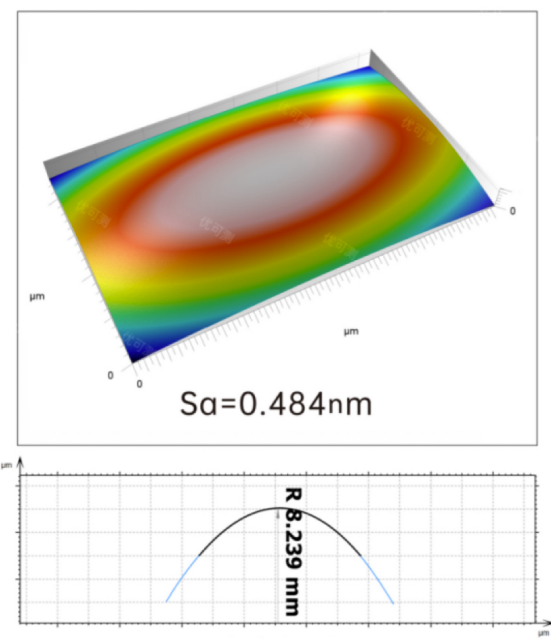

(3) Atometrics White Light Interferometer AM-7000 Series Inspecting a 3D Printed Aspheric Lens:

Compared to traditional lens manufacturing, 3D printing enables the design and fabrication of complex shapes, allowing aspheric lenses to better meet specific optical requirements. It also facilitates personalized customization, manufacturing lenses tailored to exact needs, whereas traditional methods often require large batch production. Thus, 3D printing offers greater flexibility and efficiency for producing aspheric lenses.

Measurement of Surface Roughness and Radius of Curvature on a 3D Printed Aspheric Lens

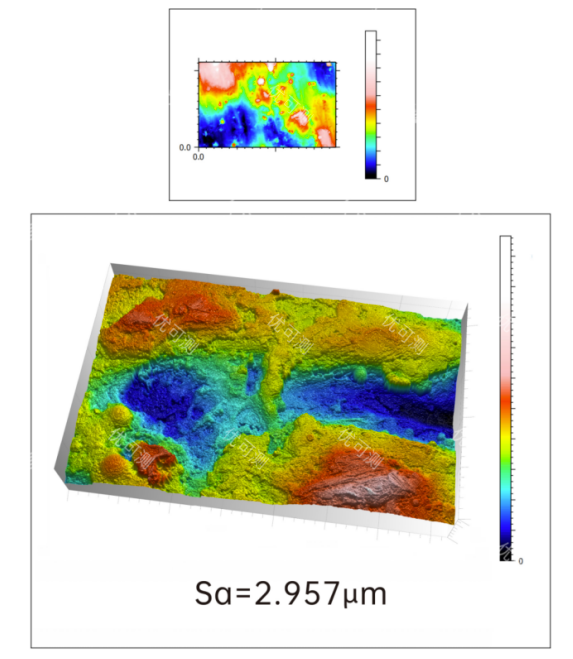

(4) Atometrics White Light Interferometer AM-7000 Series Inspecting a 3D Printed Metal Sample:

Surface Roughness Measurement on a 3D Printed Metal Sample

Atometrics White Light Interferometer AM-7000 Series achieves sub-nanometer accuracy.

Highest RMS Repeatability: 0.002 nm

Equipped with large-stroke piezoelectric ceramics

Maximum Scanning Speed: 400 μm/s

3200 Hz acquisition rate combined with the industry-first SST+GAT algorithm enables instantaneous acquisition of up to 5 million data points.

Based on white light interferometry and optical phase measurement, it delivers detection accuracy better than 1 nm at any magnification.

Incorporates internationally standardized measurement tools, enabling efficient 3D data analysis to easily address diverse industry needs.