With the development of science and technology, optical lenses are widely used in people's daily lives. Improving the product quality and performance of optical lenses plays a crucial role in enhancing the competitiveness of the modern optical industry. To achieve this, reliance is not only placed on advanced processing technologies but also, critically, on precision measurement technology. Parameters such as surface roughness, surface form (figure), and radius of curvature are key factors affecting the quality control (QC) and performance of optical lenses. Choosing a detection method characterized by high precision, high speed, and user-friendly operation can help reduce the scrap rate of optical lenses and further enhance the competitiveness and core technology of the optical lens industry.

I. Classification of Optical Lenses:

Based on lens shape, they can be divided into two main categories: spherical lenses and aspheric lenses.

1. Spherical Lenses refer to lenses where one surface is spherical and the other is flat, or where both inner and outer surfaces are spherical. Spherical lenses are generally categorized as concave mirrors or convex mirrors. Spherical lenses suffer from optical aberrations. Consequently, aspheric lenses, designed to reduce, compensate for, and correct aberrations and distortions, emerged.

2. Aspheric Lenses are lenses whose surface shape is defined by a higher-order polynomial equation, meaning the radius of curvature varies across different points on the surface; the curvature is not perfectly circular. In optical systems, such lenses can improve imaging quality by correcting various aberrations, expanding the field of view, and enhancing system performance, thereby increasing the system's resolution. One or several aspheric lenses can replace many spherical lenses, thereby reducing product manufacturing costs, simplifying production processes and structures, and to some extent, reducing the weight of optical products. Currently, aspheric lenses have gradually become one of the most widely used optical components in optical products.

Aspheric technology is commonly applied in optical instruments such as high-end cameras, astronomical telescopes, precision microscopes, and optical measurement instruments to achieve clearer and more accurate imaging.

In the fields of semiconductor lasers and fiber optic communications, aspheric technology can improve beam focusing and coupling efficiency, enhancing device performance and stability.

In the medical device field, aspheric lenses enable precise positioning and focusing of laser beams, improving the accuracy and safety of laser surgery. They are also used in the manufacturing of medical devices like intraocular lenses (IOLs) and spectacle lenses, enhancing the effectiveness and comfort of vision correction.

In the aerospace and aviation fields, aspheric lenses can improve the imaging accuracy and stability of space optical equipment like satellites and telescopes, adapting to extreme space environments. In aviation components like aircraft and missiles, aspheric technology can also enhance the performance of optical guidance systems, improving navigation and guidance accuracy.

II. Precision Measurement Requirements for Optical Lenses:

Surface Roughness refers to the unevenness of a surface characterized by small spacing and minute peaks and valleys. Smaller surface roughness indicates a smoother surface. Sa refers to the "arithmetic mean of the absolute values of the profile deviations (peaks and valleys)" within the sampling area.

Surface Form (Figure) refers to the shape and curvature of the optical lens surface. Different surface forms have varying effects on light propagation and focusing. In optics, the quality of an optical surface form is generally indicated by the PV value (Peak-to-Valley value). This typically represents the deviation between the actual lens surface and the ideal spherical surface and is a comprehensive indicator of surface error. Generally, a smaller PV value indicates a flatter surface and higher machining quality.

Radius of Curvature refers to the distance between the vertex of the optical lens and its center of curvature. It is a crucial parameter in the research, development, and production of optical components. Through precise measurement of the radius of curvature, the optical path length as light passes through the lens can be determined, aiding in meeting parameter requirements during R&D, production, and QC monitoring stages.

To achieve the desired precision standards for optical lenses, multiple precision measurements and corrective shaping are performed during the machining process. This ensures compliance with product quality standards. Through iterative processes like grinding, lapping, and polishing, the precision, quality, and performance of optical lenses are enhanced. Therefore, precision measurement is an indispensable step in the R&D, production, and manufacturing of optical lens products.

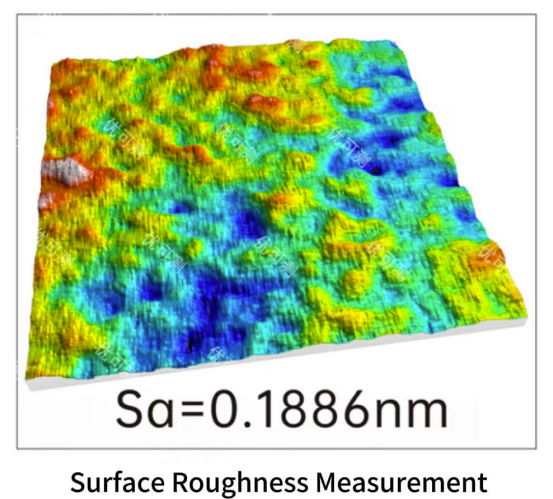

(1) Ultra-Smooth Machined Components:

In the field of precision optics, components with an Ra value < 0.3 nm are generally called ultra-smooth (or supersmooth) components. In optical systems, ultra-smooth components effectively reduce light scattering due to their extremely low surface roughness and damage-free surfaces.

Below is a case study surface roughness measurement of an ultra-smooth lens:

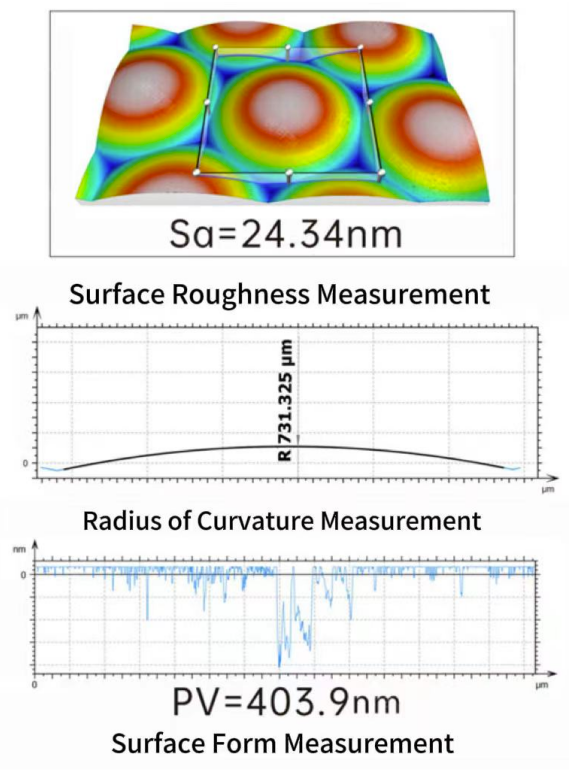

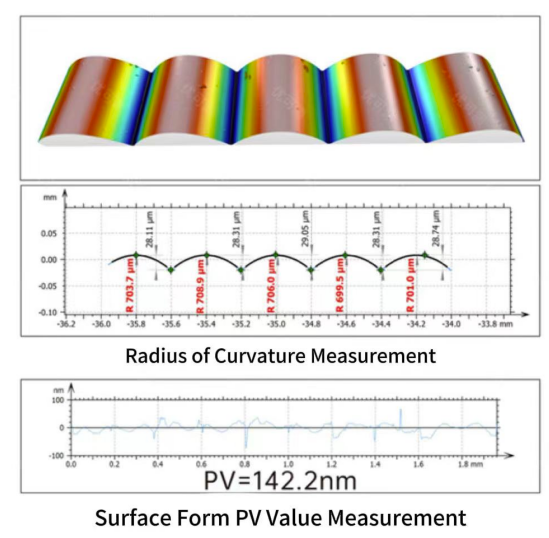

(2) Microlenses:

Microlenses are common miniature optical components used in optical systems to converge or diverge light radiation. A microlens array (MLA) is a structured array composed of multiple microlenses. It not only possesses the basic functions of traditional lenses, such as focusing and imaging, but also offers advantages like high integration density and small unit size. This structure enables efficient control and processing of light, finding wide applications in optical communications, optical imaging, laser processing, and more.

Below is a case study measuring the surface roughness, radius of curvature, and surface form PV value of a microlens array:

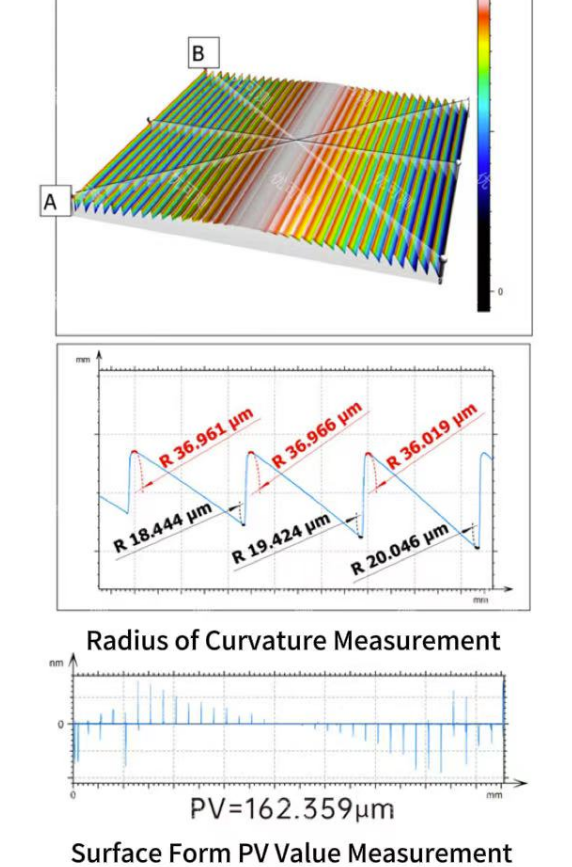

(3) Fresnel Lenses:

Fresnel lenses, also known as threaded lenses, feature a smooth surface on one side and a series of concentric grooves (from small to large) etched on the other side. This concentric groove pattern is designed based on the requirements of light interference, diffraction, relative sensitivity, and acceptance angle.

Fresnel lenses have very broad applications, commonly used in precision optics, polymer materials, mechanical processing, aviation and navigation, infrared detection, smart electronic products, light/solar concentration, and new energy photovoltaics.

Below is a case study measuring the radius of curvature and surface form PV value of a Fresnel lens:

(4) Cylindrical Lenses:

Cylindrical lenses are a special type of aspheric lens with unique optical properties, such as changing image dimensions. They can effectively reduce chromatic aberration and spherical aberration and are widely used in various optical products. As technology advances, the requirements for cylindrical lens components become increasingly stringent, making precision measurement technology crucial.

Below is a case study measuring the radius of curvature and surface form PV value of a cylindrical lens:

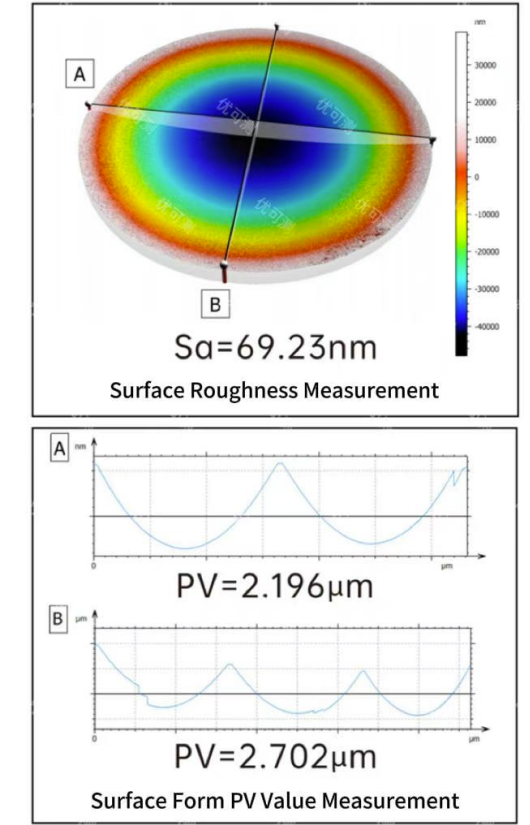

(5) Concave Mirrors, Convex Mirrors:

A concave mirror uses the inner surface of a sphere as its reflective surface, while a convex mirror uses the outer surface. Concave mirrors converge light and are commonly used in products like satellite antennas, radar systems, lamps, and telescopes. Convex mirrors diverge light and are often applied in products requiring an expanded field of view, such as corner mirrors (blind spot mirrors) and wide-angle mirrors.

Below is a case study measuring the surface roughness and surface form PV value of a concave mirror:

(6) White Light Interferometer for Surface Measurement

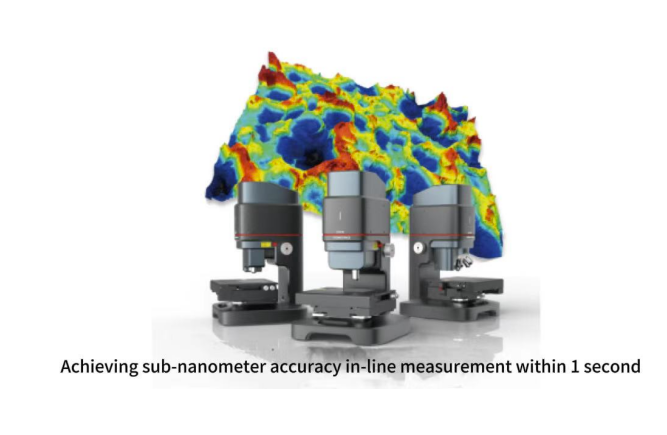

Atometrics White Light Interferometer AM-7000 Series achieves sub-nanometer accuracy.

Highest RMS repeatability reaches 0.002 nm.

Equipped with large-stroke piezoelectric ceramic devices, the maximum scanning speed is 400 μm/s.

With 3200 Hz and the industry's first SST+GAT algorithm,

it can instantly acquire up to 5-million-point clouds.

Based on the principle of white light interferometry, it achieves detection accuracy of less than 1 nm at any magnification through optical interference phase metrology.

Covers internationally standardized measurement tools commonly used in the market.

Analyzes 3D data efficiently and effortlessly, enabling you to handle diverse industry applications with ease.