Ⅰ. Principle of Spectral Confocal Displacement Sensor

The principle of Spectral Confocal Displacement Sensor is based on white light interference and chromatic dispersion. It precisely calculates the distance between the object and the sensor by measuring the interference fringes generated by light of different wavelengths reflected from the object's surface. The detailed principle is as follows:

Light Source Emission: A broadband light source inside the sensor emits white light containing multiple wavelengths. This light is transmitted through optical fibers or other optical components to the probe part of the sensor.

Chromatic Dispersion Optical System: In the probe, the white light passes through a specialized chromatic dispersion optical system that spatially separates light of different wavelengths, causing each wavelength to propagate along a distinct axial direction and forming a light cone distributed by wavelength.

Focusing and Reflection: Light of different wavelengths within the cone focuses on the surface of the measured object at different distances. When this light irradiates the object's surface, it reflects. The reflected light returns along the same path as the incident light back to the sensor.

Spectral Analysis: The returned reflected light passes through the chromatic dispersion optical system again and is then received by a spectrometer. The spectrometer analyzes the spectrum of the reflected light, detecting the intensity distribution of the different wavelength components.

Distance Calculation: Since light of different wavelengths focuses at different distances, the position where a specific wavelength focuses on the object's surface can be determined based on the wavelength component with the highest intensity in the reflected light. This allows for calculating the distance between the object and the sensor. For example, longer wavelengths focus at farther distances; if the intensity of long-wavelength light is the strongest in the reflected light, it indicates that the object is farther from the sensor. Conversely, stronger short-wavelength intensity indicates a closer distance.

Through this method, Spectral Confocal Displacement Sensor achieve high-precision non-contact surface measurement, unaffected by factors such as the object's surface color or roughness. They are widely used in precision measurement, industrial automation, optical inspection, and other fields.

Ⅱ. Spectral Confocal Displacement Sensors enable high-precision measurement of various physical quantities related to displacement and dimensions, as detailed below:

1. Precise Displacement and Distance Measurement

Micro-displacement Measurement: In precision machining and optical instrument manufacturing, they can accurately measure component displacement changes at the micron or even sub-micron level. For instance, monitoring minute displacements of optical lenses during coating processes to ensure uniform coating thickness.

Object Spacing Measurement: They can accurately measure the gap or distance between two objects. For example, in electronic device assembly, measuring the distance between a chip and a heat sink to guarantee thermal performance and electrical properties.

2. Object Dimension Measurement

Thickness Measurement: For sheet materials such as metal foil, plastic film, and glass sheets, they can precisely measure thickness. In lithium battery production, they are used to measure the coating thickness of electrode sheets, controlling battery performance and safety.

Diameter Measurement: They can measure the diameter of cylindrical objects, such as optical fibers and miniature shaft components. During optical fiber manufacturing, they monitor changes in fiber diameter in real-time to ensure transmission performance.

3. Object Surface Topography Detection

Flatness measurement: They can inspect the flatness and planarity of object surfaces, determining the presence of irregularities or warping deformations. In semiconductor wafer production, they inspect wafer surface flatness to ensure the process accuracy of chip manufacturing.

Profile Measurement: They acquire surface profile information for measuring the shape of complex objects and quality control. For example, measuring the inner wall profile of an automobile engine block to check for machining defects.

4. Position Location and Alignment

Automated Production Line Positioning: On automated production lines, they precisely determine object positions, enabling accurate robotic grasping and assembly. For instance, in mobile phone assembly lines, locating the positions of phone casings and components to ensure assembly accuracy.

Optical Component Alignment: In the assembly and adjustment of optical systems, they achieve precise alignment of optical components. For example, during camera lens assembly, accurately adjusting lens positions by measuring displacement to guarantee the imaging quality of the lens.

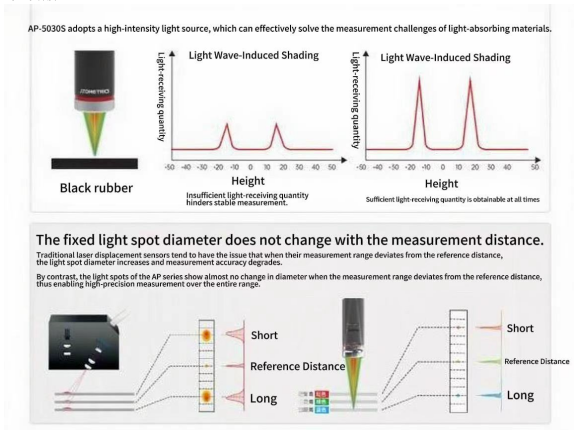

The Atometrics Spectral Confocal Displacement Sensor AP Series can measure various materials including glass, metal, rubber, etc., and can perform: thickness, warpage, coaxiality, flatness, height, axis runout, surface profile, inner diameter inspection, mechanical positioning, and more.