A profilometer is a professional instrument used for the precise measurement of surface topography, contour dimensions, and micro-roughness. Based on its working principle and application requirements, it can be classified into two main types: contact (stylus type) and non-contact (optical type). The following details its measurement capabilities and main types:

Ⅰ Core Measurement Capabilities of Profilometers

1. Geometric Profiles and Dimensions

Basic Parameters: Length, height, angle, radius, groove depth/width, diameter.

Geometric Tolerances: Straightness, roundness, parallelism, profile tolerance, coaxiality.

Complex Curved Surfaces: Convex curves, logarithmic profiles, aspheric optical contours, steep edges (supports angles > 85°).

2. Surface Micro-characteristics

Roughness Parameters: Ra, Rz, Rq, Rsk, etc. (Compliant with ISO/GB standards).

Waviness and Defects: Periodic waviness (Wa, Wt), scratch depth, pitting volume.

Nanometer-level Precision: Resolution down to sub-nanometer level (0.1 nm), capable of measuring ultra-smooth surfaces with Ra as low as 0.01 μm.

3. Special Application Extensions

Industrial Components: Bearing raceway convexity, seal structure angles.

Optical Devices: Lens aspheric curvature, freeform surface deviation.

Material Analysis: Film step height (nanometer to millimeter level), wear volume, 3D topography of microstructures.

Ⅱ Classification and Technical Features of Profilometers

1. Contact Profilometers (Stylus Scanning Type)

Principle: A diamond stylus contacts the surface, and the profile is recorded via a displacement sensor.

Applicable Scenarios:

Hard materials (metals, ceramics).

Obstructed areas like deep grooves and inner walls of holes.

High-precision contour dimension measurement (micron level).

Limitations: May damage soft materials; relatively slow scanning speed.

2. Non-contact Profilometers (Optical Type)

Technical Variants:

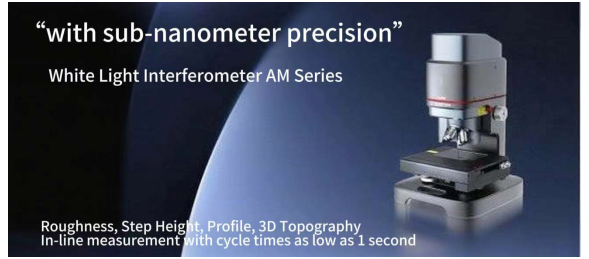

White Light Interferometers (WLI): Vertical resolution up to 0.1 nm, suitable for transparent films and nano steps.

Laser Scanners: High-speed measurement of large curvature surfaces.

Confocal Microscopes: 3D topography reconstruction, supports highly reflective surfaces.

Advantages:

Non-destructive measurement (soft gels, biological samples).

Sub-micron lateral resolution.

Supports large-area automatic stitching (>200 mm).

Limitations: Transparent or strongly light-absorbing materials may require special treatment.

3. Specialized Type s

Laser Curtain Profilometers: Online inspection of outer diameter and edge position (e.g., part sorting).

Air-bearing Guideway Profilometers: Straightness/flatness measurement of heavy workpieces (vibration resistant).

Key Factors for Selection

|

Parameter |

Contact Type |

Non-contact Type |

|

Measurement Range |

Millimeter level height/length |

Millimeter to centimeter level stitching |

|

Resolution |

Nanometer vertical resolution |

Sub-nanometer vertical resolution |

|

Suitable Materials |

Hard, opaque materials |

Soft/transparent/highly reflective materials |

|

Typical Scenarios |

Bearing raceways, precision mechanical parts |

Optical lenses, MEMS chips, thin films |

Ⅳ Surface Profiles Suitable for Measurement by White Light Interferometer (WLI)

White light interferometers offer sub-nanometer measurement accuracy, with RMS repeatability up to 0.002 nm. They are suitable for measuring microscopic profiles requiring extremely high precision, such as contours of ultra-smooth mirrors orminute structures on semiconductor chips.

2. Acquires surface 3D topography in the form of an "area," enabling comprehensive measurement and analysis of complex three-dimensional contours, such as microlens curved surfaces or 3D structures on etched wafers.

3. Utilizes non-contact surface measurement, avoiding potential scratches or damage to samples caused by traditional contact methods. Suitable for measuring easily damaged materials (e.g., photomasks, glass) and contours of soft materials (e.g., polymers, LCD panels).

4. With stitching technology, the maximum field of view can reach 300mm × 300mm, allowing high-precision contour measurement over large areas. Applicable to samples requiring large-area contour inspection, such as large metal sheets or PCB substrates.

5. Features exceptional angle capability beyond traditional limits: up to 53° for smooth surfaces and 90° for local profile inclination. Enables measurement of contours with steep angles, such as the sharp edges of cutting tools or vertical sidewalls of semiconductor etches.

6. Can be combined with various measurement tools (e.g., profile analysis, angle measurement, line roughness calculation) for multi-dimensional contour analysis. Suitable for scenarios requiring comprehensive evaluation of contour parameters, such as parts needing simultaneous inspection of surface roughness and contour shape.

Ⅴ Surface Profiles Suitable for Measurement by 3D line laser measuring instrument