I. Principle of Laser Displacement Sensors

The principle of a laser displacement sensor primarily involves emitting a laser beam and measuring the time-of-flight or phase shift of the beam from emission to reception to calculate the distance between the sensor and the target object. A common method is the triangulation principle.

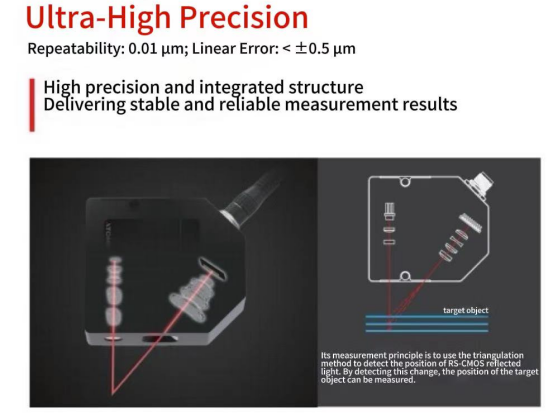

Working Method of the Triangulation Principle: The laser displacement sensor emits a laser beam that strikes the surface of the target object. The laser light reflects off the object's surface, and this reflected light is collected by the sensor's internal optical system and focused onto a Position Sensitive Detector (PSD) or a Charge-Coupled Device (CCD). Based on the principles of similar triangles, knowing the laser emission angle, the approximate distance range between the sensor and the object, and the position of the light spot imaged on the detector, the precise distance from the object to the sensor can be calculated.

Schematic Diagram of Laser Triangulation Principle

Application Scenarios: Widely used in industrial automation production lines for object dimension measurement, object surface profile inspection, and other scenarios. Examples include dimensional inspection of automotive components, flatness measurement of electronic product housings, etc.

Atometrics Triangular Laser Displacement Sensor SL Series: Can measure displacement, height, thickness, and mechanical positioning, with measurement accuracy up to the micrometer level.

II. What Can Laser Displacement Sensors Measure?

Laser displacement sensors can perform high-precision measurements of various physical quantities related to displacement, distance, and dimensions, specifically as follows:

1. Displacement and Distance

2. Object Dimensions

3. Object Surface Topography

4. Position and Location

Furthermore, laser displacement sensors can also be used for liquid level measurement, monitoring changes in the height of liquid surfaces, such as in chemical storage tanks or water treatment facilities. They are also used to monitor the positional changes of objects during material processing to achieve precise process control, such as in laser cutting, welding, and other processes.

Atometrics Triangular Laser Displacement Sensor SL Series: Can measure displacement, height, thickness, and mechanical positioning, with measurement accuracy up to the micrometer level.