I. Principle of Film Thickness Measurement Instruments

The Atometrics Film Thickness Measurement Instrument operates based on the optical interference principle. The specific principle is as follows:

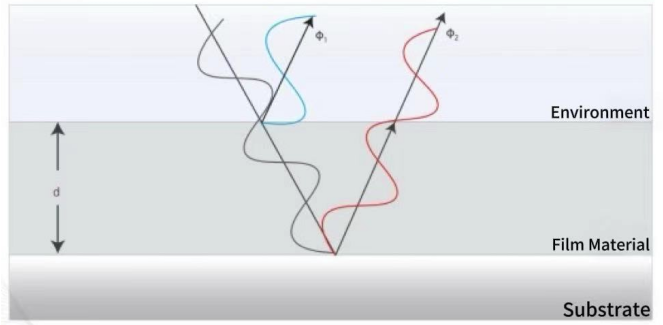

The instrument emits light waves of different wavelengths that penetrate the sample film layers. The light reflected from the upper and lower surfaces of the film is received by the instrument. The reflected light waves interact, creating a phase difference that leads to constructive or destructive interference. When the phase difference is an integer multiple of the wavelength, constructive interference occurs, resulting in maximum reflectivity. When the phase difference is a half-wavelength, destructive interference occurs, resulting in minimum reflectivity. For phase differences between integer and half-wavelength multiples, the reflectivity falls between the maximum and minimum values.

This variation in phase difference depends on the film thickness (d) and the refractive index (n). Given the optical parameters (n, k) of the material, the reflectivity R(λ, d, n, k) of this optical measurement system can be derived.

By assigning values to the optical parameters (n, k) within the instrument, the theoretical reflectivity R can be calculated. This calculated R is then compared to the measured reflectivity R' obtained by the instrument. Using powerful algorithms, when the calculated reflectivity curve R perfectly fits the measured reflectivity curve R', the film thickness (d) can be determined by analyzing the interference pattern.

In theory, only films made of transparent or semi-transparent materials allow light waves to penetrate and can thus be measured using this principle. However, for some non-transparent materials, such as metals, if the metal film is only a few hundred nanometers or even just a few nanometers thick, it may still allow partial penetration of light waves, enabling accurate thickness measurement in such cases as well.

II. What Can a Film Thickness Measurement Instrument Measure?

Film thickness measurement instruments can measure various types of films, as detailed below:

1. Classification by Material

Metal Films: Such as aluminum, copper, and gold films, commonly used in electronic devices, optical coatings, etc. For example, in semiconductor chip manufacturing, metal films are used as wires or electrodes, requiring precise thickness measurement to ensure device performance.

Inorganic Non-Metal Films: Such as silicon dioxide (SiO₂) films, silicon nitride (Si₃N₄) films, etc., widely used in integrated circuits, solar cells, etc. Taking solar cells as an example, the silicon dioxide film acts as an anti-reflection layer, and precise control of its thickness is crucial for improving the cell's photoelectric conversion efficiency.

Organic Films: Including polyimide (PI) films, polyester (PET) films, etc., commonly found in flexible electronics, packaging materials, and other industries. For instance, the thickness of the polyimide film in flexible displays affects the display's flexibility and performance.

Biological Films: Such as protein membranes, lipid membranes, etc., with important applications in biomedical research, drug delivery, etc. Studying the thickness of biological membranes is significant for understanding cell structure and function, as well as drug delivery processes in organisms.

2. Classification by Application Scenario

Electronics Industry: Measures the thickness of photo resist films, dielectric films, metal wiring films, etc., on semiconductor wafers to ensure manufacturing precision and chip performance.

Optical Coatings: Measures the thickness of coatings on various optical lenses, mirrors, filters, etc., to achieve specific optical performances such as anti-reflection, reflection, and beam splitting.

Materials Research: Precisely measures the thickness of film materials during the development of new materials, aiding in the study of material growth mechanisms and the relationship between properties and thickness.

Packaging Industry: Inspects the thickness of packaging materials like plastic films and aluminum foil to ensure packaging quality and properties such as barrier performance and strength.

Printing Industry: Measures the thickness of photo resist layers on printing plates and the thickness of ink films during the printing process, playing an important role in controlling print quality.

Atometrics Film Thickness Measurement Instrument AF Series: Rapidly measures the thickness of films made from various materials; can measure up to 10 layers with an accuracy of up to 0.1 nm; applicable to multiple scenarios including offline, online, and mapping.