I. Principle of 3D Line Laser Measurement Systems

The working principle of a 3D Line Laser Measurement System is based on Laser Triangulation. It projects a laser line onto the object surface and uses a camera to capture the reflected light, calculating the object's three-dimensional coordinate information to acquire its 3D shape and dimensional data. The specific principles are as follows:

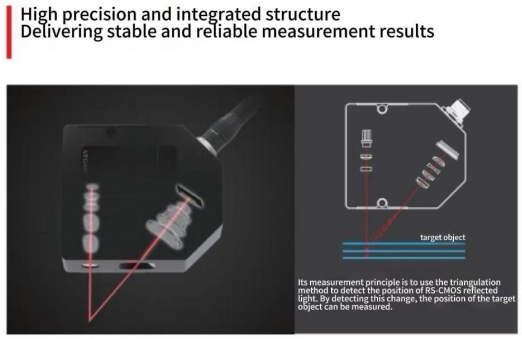

Schematic Diagram of 3D Line Laser Measurement Principle

Laser Projection: The laser emitter within the 3D line laser measurement system projects a laser beam. This beam is shaped by an optical system into a laser line, which is then projected onto the surface of the target object. This laser line forms a bright line on the object surface, whose shape and position change according to the surface contours of the object.

Image Acquisition: A camera, positioned at a specific angle to the laser emitter, captures images of the laser line on the object surface. Due to variations in the object's surface height, the position of the laser line on the camera's imaging plane changes correspondingly. In the images captured by the camera, the grayscale value distribution of the laser line reflects the contour information of the object surface.

Triangulation Principle: A triangle is formed based on the geometric relationship between the laser emitter, the camera, and a specific point on the target object's surface. Knowing the relative position and orientation (i.e., the distance and angle between them) of the laser emitter and the camera, and by measuring the position of the laser point on the camera's imaging plane and the angle between the laser line and the camera's optical axis, the distance from the measured point to the camera (i.e., the height information of that point on the object surface) can be calculated using trigonometric relationships.

Data Processing and 3D Reconstruction: The measurement system processes the large number of images acquired by the camera, identifies the positional information of each point along the laser line, and calculates the corresponding 3D coordinates based on the triangulation principle. By integrating and processing these 3D coordinate points, a 3D model of the target object can be reconstructed, obtaining detailed information such as the object's shape and dimensions.

3D surface measurement: By continuously moving the measurement system or the target object, performing point-by-point scanning of the object surface, the complete 3D data of the object can be acquired, enabling high-precision 3D measurement and modeling of the object.

II. Functions and Advantages of Atometrics3D Line Laser Measurement Systems

Main Functions:

1. Dimensional Inspection: Measures height, depth, width, thickness, angle, volume, etc.

2. Appearance Inspection: Detects burrs, bumps/dents, foreign objects, cracks/breaks, etc.

3. Form/Shape Inspection: Checks coplanarity, flatness, warpage, gaps, etc.

4. Rich Measurement Tools: Includes various functional modules such as visual positioning, visual calibration, 3D measurement, and stitching measurement.

Equipment Advantages:

1. Ultra-High Precision: 4096 points/profile; high accuracy in X and Z axes; high contour data interval and linearity accuracy.

2. Ultra-High Speed: Fastest scanning frequency of 40 kHz; ROI free cropping function can improve scanning speed.

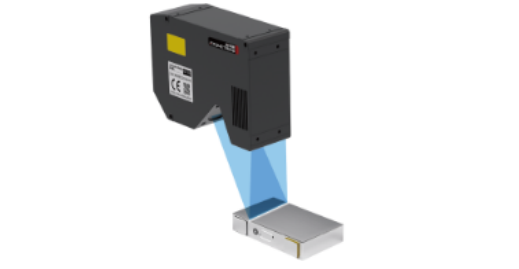

3. Compact Size: Unique optical path design, compact body easy to integrate.

4. Feature-Rich: Powerful software functionality and professional after-sales support.

5. Strong Adaptability: Stable m easurement of various materials, shapes, and reflective surfaces.

Atometrics3D Line Laser Displacement Sensor AR Series can measure thickness, flatness, 3D profile, profile degree, step height, position degree, coplanarity, defects/flaws, etc., with the highest accuracy reaching the sub-micron level.