Sliding and healing of frictional interfaces that appear stationary recently published in Nature has sparked widespread discussion. This research introduces a novel concept—"invisible interfacial sliding"—unveiling the mystery behind "stationary" frictional interfaces and demonstrating that all is in motion at microscopic scales. What value does tribology research bring? Dr. Atometrics explores this with you today.

Defining Tribology

Tribology is the discipline investigating surface friction behavior, examining the fundamental theories and techniques of the interrelationship among the friction, lubrication, and wear on interacting surfaces with relative motion or motion tendencies. Its findings profoundly impact industrial technological innovation, energy efficiency enhancement, and material longevity extension.

As an interdisciplinary field(Explain:It refers to a comprehensive discipline category that is closely related to the knowledge systems of two or more different fields and has developed with the help of their achievements), tribology centers on mechanical engineering while intersecting with chemistry, materials science, biomedical engineering, bionics, and energy/power engineering. Its broad relevance makes tribological research vital across industries.

Tribology's Cross-Industry Impact

1.Manufacturing

Tribological research reduces energy dissipation by 15–30% and extends equipment service life. Friction-induced mechanical wear accounts for >70% of component failure causes. Implementing tribological optimization minimizes downtime maintenance costs and enhances production throughput.

Application Example: Engine piston ring coatings cut cylinder friction, lowering fuel consumption; wear-resistant materials selection optimizes component durability

2.Aerospace

Tribology research overcomes extreme-environment bottlenecks where demanding conditions—high velocity (≥Mach 5), elevated temperature (>1,200°C), and extreme loading (>3 GPa)—impose stringent requirements on material tribological behavior. Consequently, scientists develop thermal barrier coatings (TBCs) achieving 40–60% wear rate reduction and engineer superlubricity materials ensuring device functionality under critical operational regimes.

3.Biomedical

Tribological advancements enhance implant safety and patient comfort. Wear debris from artificial joints may induce periprosthetic osteolysis (bone resorption inflammation), shorten the lifespan of the implant. Consequently, the wear resistance of different materials can be studied to optimize the lifespan of the implant.

Microelectronics & Precision Manufacturing

Micro/nano-tribological phenomena in MEMS devices and chip packaging directly govern product reliability. For instance, diamond-like carbon (DLC) coatings (<2nm thickness) on HDD read-write heads extend wear lifespan to >100,000 service hours. Such research necessitates nanometer-level resolution surface topography characterization for process refinement.

Rapid Topography Measurement Accelerates Research

Atometrics AM-Series White Light Interferometers integrate high-speed nano-piezoelectric stages with Scientific research-grade cameras (2.3/5.0 megapixels), enabling sub-nanometer accuracy wear topography measurement. This system has catalyzed breakthrough research across academia and industry.

Case Studies

Harbin Institute of Technology & CATL 21C Lab

Microstructure and High-Temperature Tribological Properties of Ti/Si Co-Doped DLC Films Fabricated by Dual-Target Reactive HiPIMS

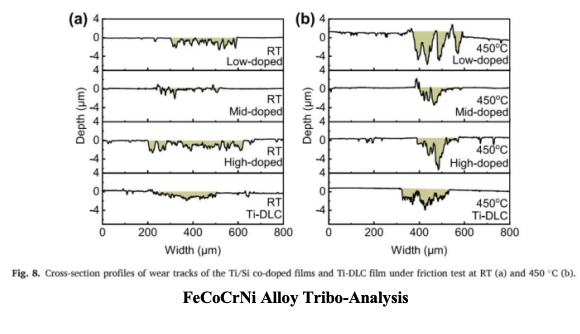

FeCoCrNi Alloy Tribo-Analysis

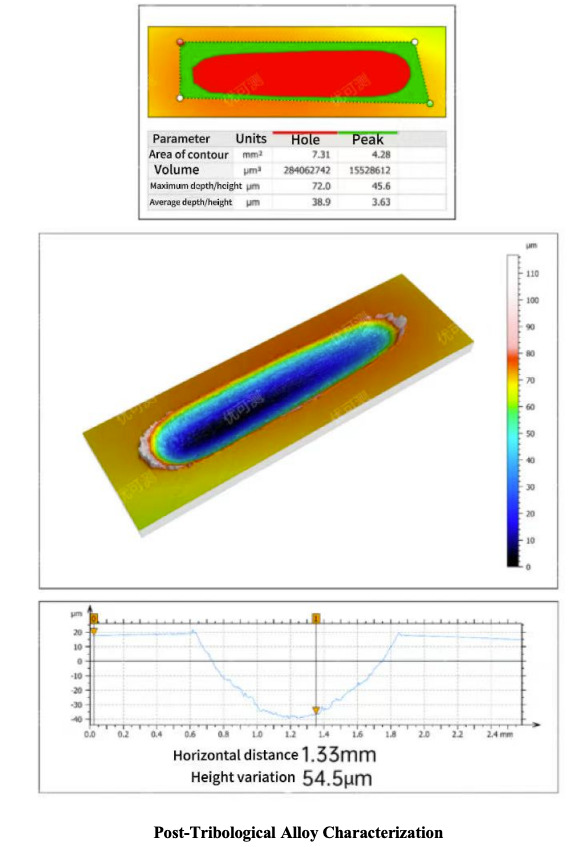

Post-Tribological Alloy Characterization