1.In the Field of Dental Restoration, What is Affected by Surface Roughness and Microscopic 3D Topography?

Bacterial Adhesion:

The surface roughness of dentures and implants affects the adhesion of bacteria and fungi such as Streptococcus mutans, Candida albicans, Actinomyces viscosus, and Candida albicans. Greater surface roughness correlates with stronger adhesion of bacteria and fungi. These microorganisms can easily cause oral diseases like stomatitis in dental restoration patients. Therefore, measuring and controlling the surface roughness of dentures and implants is essential to reduce bacterial and fungal adhesion.

Denture Calculus (Tartar):

The surface roughness of dentures is a key factor in the formation of denture calculus. The rougher the denture surface, the stronger the adhesion of dental plaque. Denture calculus forms due to the calcification of plaque that remains attached to the same area of the denture over a long period. Therefore, measuring and controlling denture surface roughness is necessary, and patients also need to clean their dentures regularly to reduce calculus formation.

Staining/Pigmentation:

Denture staining is related to many factors, such as dietary habits, type of denture cleaner, denture cleaning habits, material properties of the denture itself, and manufacturing processes. Relevant studies indicate that most stains deposit on the plaque adhering to dentures. Denture surface roughness is positively correlated with staining – the greater the roughness, the more pronounced the staining. Therefore, measuring and controlling denture surface roughness is required to reduce staining during use and enhance the color stability of the denture.

Friction and Wear:

Greater denture surface roughness can more easily irritate the oral mucosa. Reduced mucosal resistance can lead to plaque adhesion and deposition, causing oral diseases and pigmentation, affecting aesthetics. Simultaneously, it can reduce the denture's corrosion resistance, impacting its lifespan.

Soft Tissue Adhesion and Deposition:

Relevant studies show that smaller implant surface roughness correlates with stronger adhesion and proliferation of epithelial cells and fibroblasts, which is more conducive to soft tissue healing. Therefore, measuring implant surface roughness is necessary to improve implant materials and processes.

Osteoblast Proliferation and Differentiation:

Relevant studies indicate that the surface roughness and micro-topography of implants affect the interface reaction between bone cells and the implant, consequently influencing osteoblast proliferation, differentiation, etc. Therefore, measuring and controlling implant surface roughness and microscopic 3D topography is essential. This is where white light interferometers for surface measurement are needed.

2.Atometrics's Dental Restoration Material Testing Case Study

Recently, Atometrics's White Light Interferometer AM-7000 series has been successfully installed and put into operation at a dental school ranked within the top 50 in the QS World University Rankings. The school primarily uses it to measure the 3D profiles of implants and the surface roughness of dentures to support research on dental restoration materials and techniques by faculty and students. Below are some example measurement results:

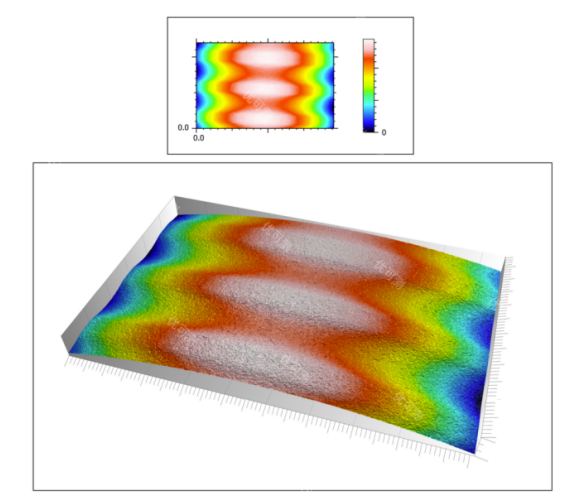

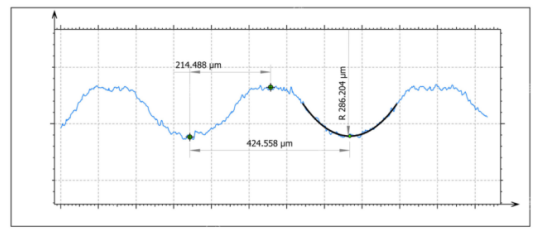

Implant Profile Measurement Results:

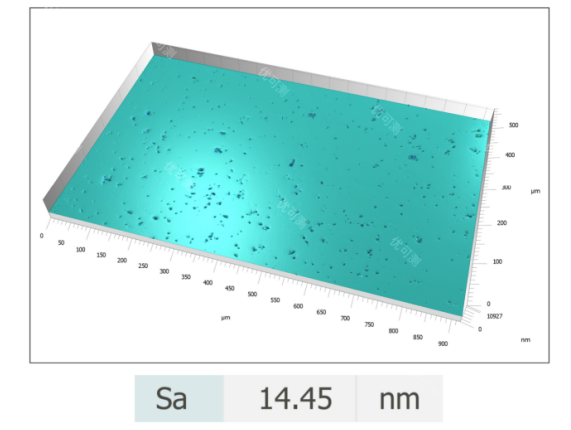

Denture Surface Roughness Measurement Results:

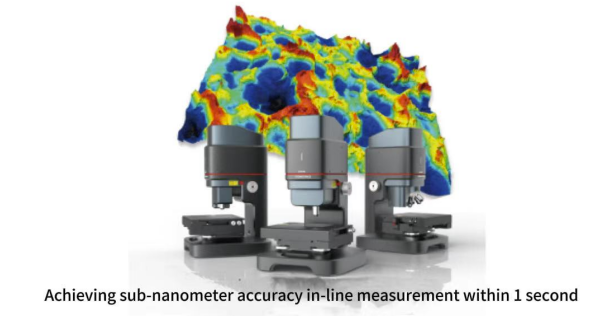

Atometrics White Light Interferometer AM-7000 Series achieves sub-nanometer accuracy.

Highest RMS repeatability reaches 0.002nm. Equipped with large-stroke piezoelectric ceramic devices, the maximum scanning speed is 400μm/s.

With 3200Hz and the industry's first SST+GAT algorithm, it can instantly acquire up to 5 million point clouds.

Based on the principle of white light interferometry, it achieves detection accuracy of less than 1nm at any magnification through optical interference phase metrology.

Covers internationally standardized measurement tools commonly used in the market. Analyzes 3D data efficiently and effortlessly. The advanced interferometric surface profiler enables you to handle diverse industry applications with ease.

If you are facing measurement challenges and are interested in the above applications, please visit the Atometrics official website for more details. Atometrics provides dedicated engineers to connect with you, offering free sample machine demonstrations and testing services nationwide!