As a commonly used medical device for cardiac interventional surgery, heart stents play a vital role in treating heart disease. Firstly, heart stents can unblock blood vessels, reduce myocardial ischemia and cardiac burden, filling the gaps left by traditional treatment methods. Secondly, the manufacturing materials and surface roughness of heart stents are crucial for treatment efficacy.

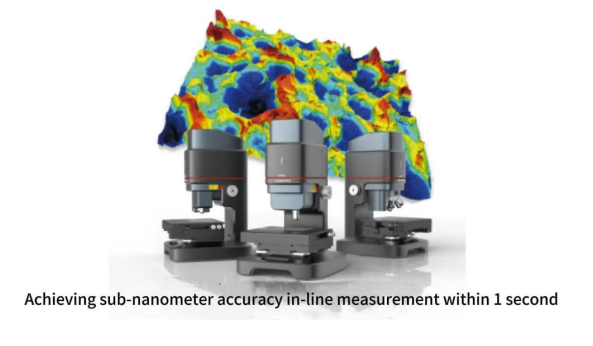

Below, Dr. Atometrics will introduce the application case of the Atometrics White Light Interferometer AM-7000 Series in measuring the surface roughness of heart stents.

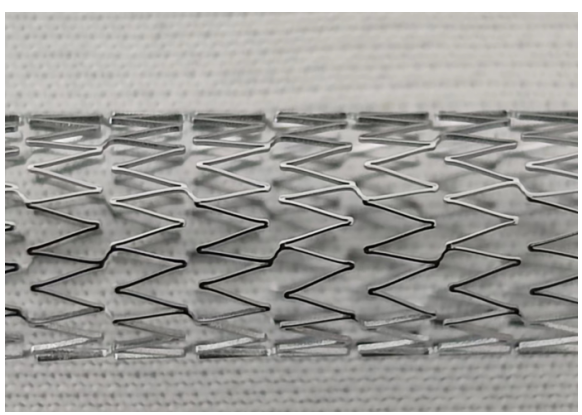

I. What is a Heart Stent?

A heart stent, also known as a "coronary stent," is a common medical device used in cardiac interventional procedures. It is typically employed to treat conditions such as acute myocardial infarction (heart attack), exertional angina, unstable angina, Tetralogy of Fallot, or other complex congenital heart diseases. For patients, a heart stent can unblock blood vessels, expand narrowed vessels, increase blood flow, reduce myocardial ischemia, and lessen cardiac burden.

The advent of heart stents filled a void in traditional treatment methods. In the past, treatment for cardiovascular diseases primarily relied on medication and open surgery, which had certain limitations: medication requires long-term use, has limited efficacy, and can lead to drug tolerance and side effects; while open surgery carries significant surgical trauma, higher risks, and a longer recovery period. In contrast, heart stents offer patients a more convenient, safer, and more effective treatment option. Firstly, heart stent procedures involve minimal surgical trauma, relatively faster recovery, fewer postoperative complications, significantly reducing patient suffering and recovery time. Secondly, heart stent procedures carry lower risks, higher success rates, and more stable treatment outcomes, effectively improving patients' quality of life.

The primary materials used for manufacturing heart stents are stainless steel, cobalt-chromium alloy, or nickel-titanium alloy (Nitinol). Among these, traditional heart stents are primarily simple metal mesh tubes that can be selected and implanted based on the patient's vessel size and shape. Additionally, there are drug-eluting stents (DES); the coating on these stents releases medication continuously, effectively preventing vessel restenosis by inhibiting neointimal hyperplasia (pipeline cell proliferation), preventing thrombosis, and enhancing the long-term efficacy of the procedure.

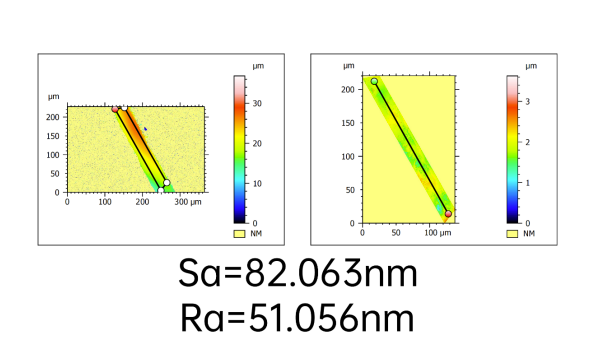

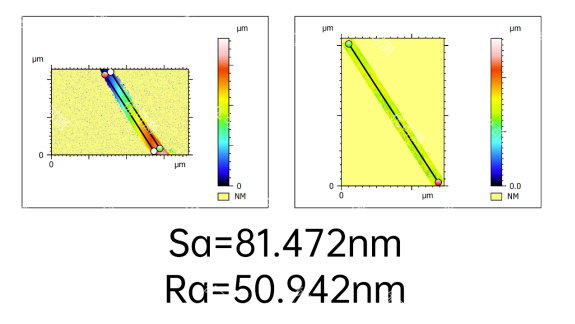

II. Heart Stent Surface Roughness Measurement

The production of heart stents has stringent requirements. Among them, when the surface roughness (Ra) of a heart stent is > 10 μm, it can affect the mechanical properties, biocompatibility, and transfer mechanisms at the stent-body interface. When 10 nm < Ra < 10 μm, the impact on mechanical properties at the interface is smaller, but the effect on biocompatibility is more significant. Generally, micrometer-level surface roughness facilitates cell adhesion, significantly enhancing the biocompatibility of the stent material. Different types and structures of heart stents have varying surface roughness requirements. If the surface roughness does not meet the specified requirements, risks such as puncturing blood vessels or affecting platelet passage can arise, impacting treatment efficacy. Therefore, controlling the surface roughness of heart stents is essential.

Below is an application case using the Atometrics White Light Interferometer AM-7000 Series to measure the surface roughness of a heart stent:

Surface roughness measurement of the heart stent's inner wall

Surface roughness measurement of the heart stent's outer wall

Atometrics White Light Interferometer AM-7000 Series achieves sub-nanometer accuracy.

Highest RMS repeatability reaches 0.002 nm.

Equipped with piezoelectric ceramic devices, the maximum scanning speed is 400 μm/s.

With 3200 Hz and the industry's first SST+GAT algorithm,

it can instantly acquire up to 5-million-point clouds.

Covers internationally standardized measurement tools commonly used in the market.

High precision 3D profiler, enabling you to handle diverse industry applications with ease.