Gold Fingers are common electronic components used to connect circuit boards to other electronic devices. They offer advantages such as high precision, high reliability, and high stability, and are widely used in industries like electronics, communications, computers, and automotive.

With the rapid development of electronic science and technology, the performance and dimensional requirements for Gold Fingers are becoming increasingly stringent. Therefore, high-precision measurement of various parts of the Gold Finger is necessary to control product quality, enhance product performance, and reduce customer complaints.

1. Structure and Composition of Gold Fingers

Gold Fingers are typically made of metal materials, featuring a slender, finger-like shape. They play a vital role in the electronics field by establishing circuit connections through metal contacts, enabling reliable current transmission and ensuring the proper operation of equipment. A Gold Finger primarily consists of two parts: the spring contacts and the base. The spring contacts are usually made of elastic metal materials such as phosphor bronze or copper alloys, possessing certain compressibility and elasticity to adapt to different connection environments and pressures. The base is typically made of metal or plastic materials and is used to secure the spring contacts and the connector housing.

2. Function and Applications of Gold Fingers

Gold Fingers are widely used in industries such as electronics, communications, computers, and automotive.

In the electronics industry, Gold Fingers are used to connect circuit boards to other electronic devices, enabling signal and circuit transmission control and ensuring proper device operation. In devices like TVs, mobile phones, and computers, Gold Finger connectors can transmit audio and video signals to displays or speakers, enabling A/V playback functionality.

In the communications industry, Gold Fingers are used to connect antennas to circuit boards, enabling the transmission and reception of wireless signals.

In computer equipment, Gold Fingers are used to connect hard drives to motherboards, enabling data reading, writing, and storage.

In automotive equipment, Gold Fingers are used to connect electronic control modules (ECUs) and sensors, enabling vehicle control and monitoring.

3. Inspection Requirements for Gold Fingers

Gold Fingers have numerous gold-plated conductive spring contacts. Different applications and products have varying requirements for the material, number, contact area, height, and plating thickness of these spring contacts. Therefore, precise measurement of the Gold Finger spring contacts is essential to verify compliance with design specifications.

Dimensional Measurement: Measuring dimensional parameters of the Gold Finger spring contacts, such as length, width, and height, to ensure they meet design requirements. Among these, the accuracy of the spring contact height critically impacts the connection and stability of the Gold Finger. Inaccurate spring height can lead to poor connections, signal interference, and other issues, ultimately affecting device performance and stability.

Surface Roughness Measurement: Measuring the surface roughness of the Gold Finger spring contacts to ensure the quality of contact with other devices.

Conductive Layer Thickness Measurement: Measuring the thickness of the conductive layer (e.g., metal plating) on the Gold Finger spring contacts to ensure its conductive performance and corrosion resistance.

4. Atometrics Gold Finger Spring Contact Height Inspection Case Study

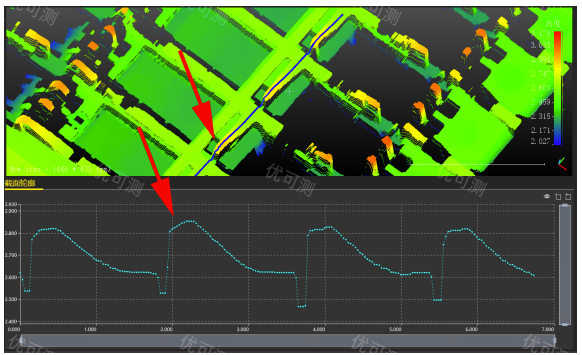

Recently, a company wanted to measure the height distance from the Gold Finger spring contacts to a reference plane to control product quality, improve production efficiency, and reduce customer complaints. Upon receiving the customer's requirement, Atometrics engineers selected the 3D Line Laser Measuring Instrument AR-7020 to create a measurement solution. Partial measurement results are shown below:

After measurement is completed, the software can analyze and process the results to determine if the Gold Finger spring contact height meets standard requirements. It also features statistical analysis functions, such as calculating values like the mean (average) and standard deviation, to evaluate the accuracy and stability of the measurement results.

Upon receiving the inspection report, the customer expressed high satisfaction with the fine detail of the product images scanned by the 3D Line Laser Measuring Instrument and the ability to obtain the required spring contact height values directly and precisely.

Seizing this opportunity, Atometrics also hopes to help more enterprises, universities, and research institutes solve their measurement challenges!

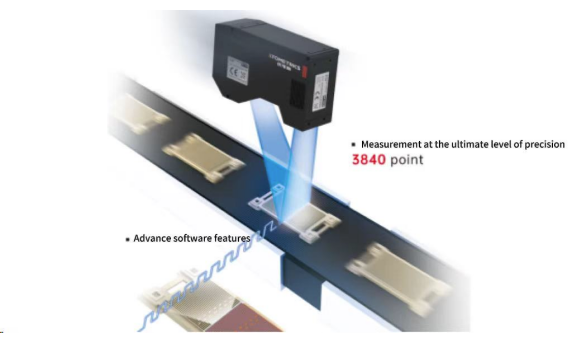

Atometrics's 3D Line Laser Measuring Instrument AR-7000 Series is a non-contact surface measurement device based on laser technology. It can perform inspections such as contour detection, defect detection, flatness, planarity, and height difference on samples.

It utilizes 3840 points to finely represent product topography, significantly enhancing image quality and detail level.

Simultaneously, it boasts powerful software functionality, equipped with various 3D inspection tools and algorithms. It also supports multi-head stitching to meet diverse stitching scenario requirements.

If you are facing measurement challenges and are interested in the above application, welcome to contact us.

Dedicated engineers will connect with you, providing free sample machine demonstrations and testing services nationwide!