I. Functions and Advantages of Atometrics Laser Displacement Sensors

Main Functions:

1. Multi-Parameter Measurement: Measures height, step height, thickness, gap, vibration, stroke, and shape.

2. Special Object Measurement: Features dedicated measurement modes for rough surfaces, mirrored surfaces, and semi-transparent objects.

Advantages:

1. High Precision: High repeatability of 0.01 µm and high linear accuracy, meeting the requirements of most application scenarios.

2. Fast Sampling: Ultra-high-speed 160 kHz sampling rate ensures stable measurements.

3. Diverse Models: Multiple models available to suit different measurement needs, applicable to objects of various colors, materials, and surface conditions.

4. Easy Operation: Simple to operate and install, with straightforward wiring and parameter configuration.

II. Application Industries for Laser Displacement Sensors

Laser displacement sensors are widely used across multiple industries due to their advantages of high precision, non-contact surface measurement, and strong anti-interference capability. Below are some of the main application industries:

Industrial Automation: Used for robotic arm positioning on production lines, workpiece dimension inspection, surface roughness measurement, etc. Also detects material overlap, controls manipulator position, thereby improving the automation level of production lines and product quality.

Automotive Manufacturing: Plays a significant role in processes such as body welding, component dimension inspection, and coating surface quality inspection. Examples include inspecting vent closing precision, monitoring millimeter-level deformation on tire surfaces, and capturing the position of rings in new energy vehicles.

Electronics Manufacturing: Can detect substrate warpage and component orientation in electronic component processing. Also measures the dimensional accuracy of electronic device housings, screen thickness and flatness, and the positional accuracy of components on circuit boards.

Robot Positioning: In application scenarios like robot navigation, automated assembly, and intelligent inspection, provides high-precision position information for robots, aiding in precise motion control and operation.

Aerospace: Used for the inspection and monitoring of key aircraft parts like skins and wings. Also applied in the profile measurement of aero-engine blades, dimensional inspection of aircraft structural components, and assembly accuracy control.

Logistics & Warehousing: Helps Automated Guided Vehicles (AGVs) achieve precise path planning and positioning by measuring distances to fixed points or landmarks, enhancing logistics transport efficiency and accuracy. Also used to detect warehouse shelf deformation and stacking height of goods.

New Energy: In the solar photovoltaic field, enables high-precision measurement of wafer surfaces to promptly identify flatness issues, ensuring the production quality and efficiency of solar cells. In lithium battery production, measures the coating thickness of electrode sheets and the thickness/uniformity of separators.

Scientific Research: Can be used to measure material surface topography and physical properties, such as studying minor deformations during tensile tests or thickness changes of semiconductor films during growth processes.

Medical: Applicable for surgical navigation and precise control of medical devices. For example, scanning dental models to assist in creating aligners in orthodontics, or measuring 3D bone morphology to provide precise data for orthopedic surgery.

Transportation: In smart traffic and digital road maintenance, can be used for road defect detection such as cracks, rutting, and potholes. Also applicable for railway track inspection, airport runway monitoring, and can provide real-time road friction coefficient estimation for L3+ level autonomous driving.

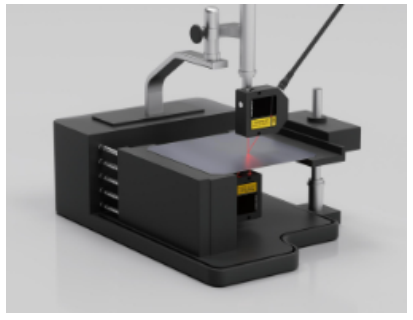

Atometrics Triangular Laser Displacement Sensor SL Series: Capable of measuring displacement, height, thickness, and mechanical positioning, with measurement accuracy up to the micrometer level.