Laser gyroscopes are widely used in aerospace, military defense, marine exploration, autonomous driving, and other fields. Their high sensitivity, strong anti-interference capability, and reliability stem from precision manufacturing technologies. Atometrics White Light Interferometers contribute to enhancing the precision of laser gyroscope mirrors, thereby improving production efficiency and yield.

In today's era of rapid technological advancement, high-precision navigation and positioning technologies have become indispensable in aerospace, military defense, marine exploration, autonomous driving, and even daily life. Behind this, the laser gyroscope, as a core component, is driving a new wave of upgrades in navigation technology with its exceptional stability and extreme accuracy.

Today, Dr. Atometrics takes you to explore the intricacies of the laser gyroscope.

I. What is a Laser Gyroscope?

A laser gyroscope is an instrument used to measure the angular motion (angular velocity or rotation angle) of a moving object, enabling precise determination of the object's orientation.

The widespread application of laser gyroscopes has significantly propelled technological progress across multiple fields. In modern aviation, maritime, aerospace, and defense industries, they play a dominant role in functions such as stable navigation, attitude control, positioning & orientation, and targeting & guidance.

II. Principle and Characteristics of Laser Gyroscopes

Laser gyroscopes utilize the Sagnac effect. In a closed-loop ring optical path, a pair of light waves emitted from the same point and traveling in opposite directions will, upon returning to the starting point after one complete circuit, exhibit different optical path lengths due to the rotation of the closed loop relative to inertial space. The resulting optical path difference is ultimately detected and used to calculate the rotational angular velocity.

Laser gyroscopes applied in the most advanced technological fields offer several characteristic advantages over traditional gyroscopes:

High Sensitivity: Capable of measuring very minute changes in angular velocity, with a large measurable dynamic range.

Strong Anti-interference Capability: Does not require receiving or radiating electromagnetic waves, resulting in extremely strong resistance to interference.

High Reliability: Can withstand extreme acceleration and severe vibrational shock.

III. Keys Determining Laser Gyroscope Performance and Accuracy

The manufacturing of laser gyroscopes is extremely challenging, with the production of the resonant cavity being the most critical aspect.

Laser light reflects multiple times within the resonant cavity, enhancing the Sagnac effect and improving measurement sensitivity.

To maintain optical path stability, reduce laser transmission loss, and enhance the performance and accuracy of the laser gyroscope, manufacturers must employ high-quality optical materials, advanced coating technologies, and precision machining.

Optical Materials: Require an extremely low coefficient of thermal expansion to minimize the impact of temperature variations on the optical path, ensuring measurement stability.

Coating Process: Coatings are used to reduce laser transmission loss within the resonant cavity and can also filter lasers of different frequencies to meet various application requirements.

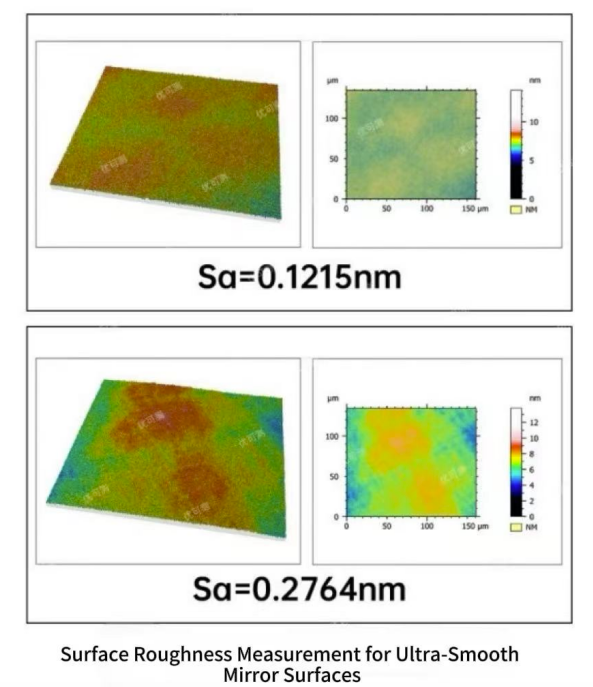

Mirror Processing: Requires extremely high surface form accuracy and surface quality. Any nanoscale defects can affect the measurement accuracy of the laser gyroscope.

Among these, the precise measurement of the surface roughness of ultra-smooth mirrors after grinding and polishing is crucial, providing key data references for improving the polishing process and increasing the yield of laser gyroscopes.

The following is a case study measuring the surface roughness of an ultra-smooth mirror using the Atometrics White Light Interferometer AM-7000 Series:

The Atometrics White Light Interferometer AM-7000 Series, coupled with unique algorithms tailored for ultra-smooth mirror samples, it enables precise surface roughness measurement for ultra-smooth optical surfaces at the sub-nanometer level. It has already been adopted by manufacturers of ultra-smooth mirrors for laser gyroscopes, providing customers with intuitive and effective data for polishing process improvement, thereby significantly enhancing customer efficiency and yield.