With the rapid development of global AI, including the training and application of large AI models (such as ChatGPT, Sora, etc.), an increasing number of computing units and servers are incorporating optical modules to enhance data transmission efficiency. According to industry forecasts, the global optical module market size is expected to exceed $80 billion by 2025, with an average annual growth rate of 15%.

In electronic equipment, the role of an optical module is to convert electrical signals into optical signals at the transmitting end, transmit them through optical fibers, and then convert the optical signals back into electrical signals at the receiving end. Optical modules typically include components such as lasers (e.g., VCSEL or EEL), modulators, photodetectors, optical fiber interfaces, and drive circuits. To ensure highly efficient transmission, high-quality control is essential during the manufacturing of each constituent unit of the optical module.

Next, Atometrics will introduce the dimensions of quality control and data inspection that leading companies in optical communication modules perform on their products during manufacturing.

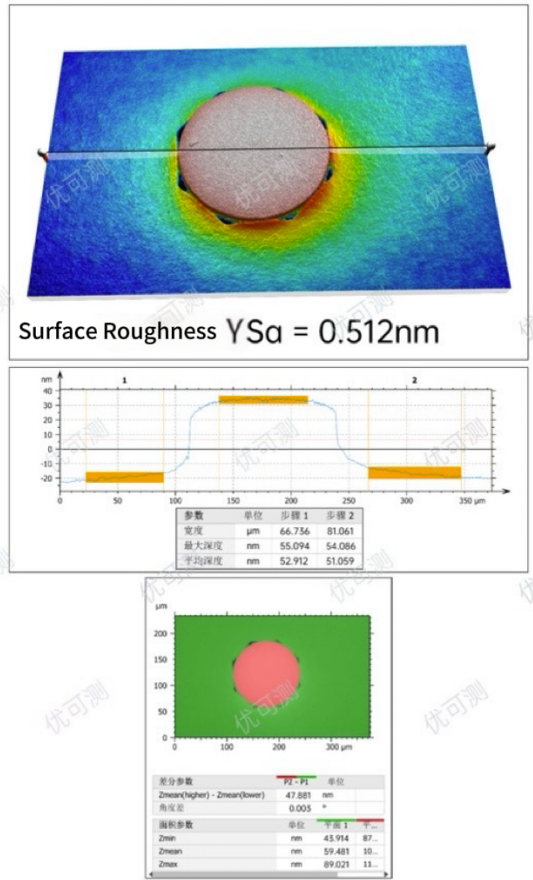

Transmitter Lasers: End-Face Dimensions, Three-Dimensional Topography

For example, "Vertical-Cavity Surface-Emitting Lasers (VCSELs)" and "Edge-Emitting Lasers (EELs)" require ensuring the three-dimensional topography and dimensions of the emission end-face to reduce optical signal loss and scattering. This necessitates inspecting the dimensions of the laser end-face to ensure efficient optical signal transmission.

Atometrics White Light Interferometer VCSEL Inspection Data

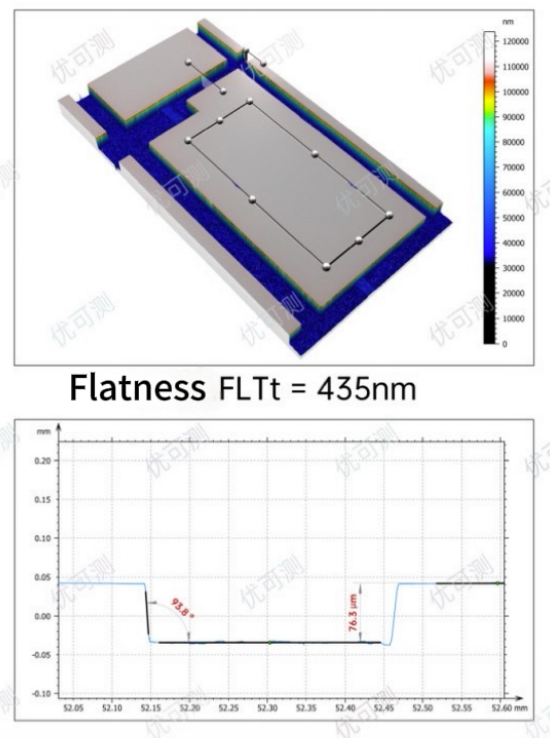

Ceramic Substrates: Step Height, Flatness

Currently, ceramic substrates are also widely used in optical communication modules. They are primarily used for packaging structures within optical modules, especially as substrates with high precision and high thermal conductivity, for mounting and securing key optical and electronic components, ensuring module reliability and performance. In various manufacturing process environments, parameters such as the step height and flatness of ceramic substrates directly affect their packaging performance, cost control, etc.

Atometrics White Light Interferometer Ceramic Substrate Inspection Data

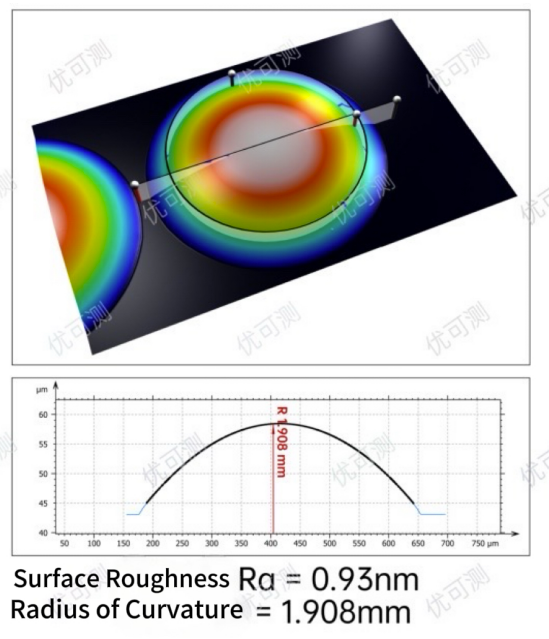

MLA: Roughness, ROC, SPD, K-value

Micro-Lens Arrays (MLAs) also play a critical role in the field of optical communications. Through efficient optical path control and high-density integration, MLAs address core challenges in optical communications such as beam collimation, coupling loss, and temperature control.

With the adoption of CPO and silicon photonics technologies, the application of MLAs in high-speed optical modules, data center interconnects, and 5G fronthaul networks will further deepen, driving optical communications towards higher bandwidth and lower power consumption.

During the manufacturing process of MLAs, parameters such as surface roughness, ROC, SPD, and K-value directly affect outcomes like optical scattering loss and beam collimation/coupling. Precise inspection of these parameters, such as surface roughness measurement, is particularly important.

Atometrics White Light Interferometer MLA Inspection Data

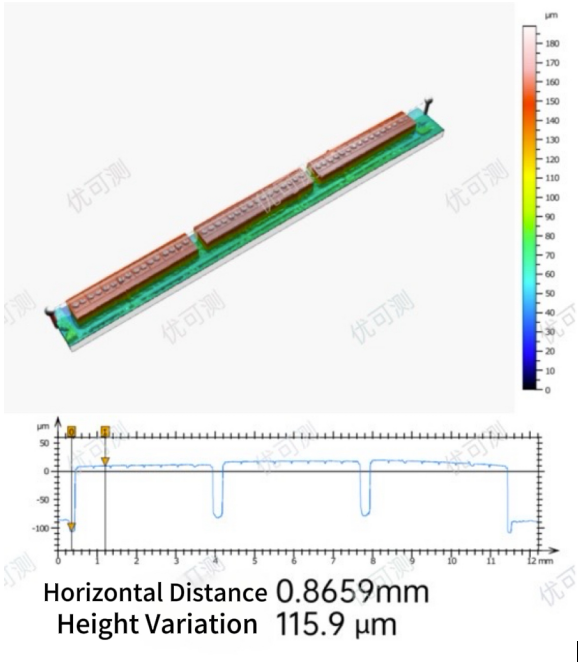

Fiber Optic End-Face: Topography, Roughness, Height

Furthermore, the topography, roughness, and height of the fiber optic end-face also directly affect the final coupling efficiency, thereby influencing the transmission quality of the optical signal.

Atometrics White Light Interferometer Fiber Optic End-Face Inspection