Rubber sealing rings are characterized by their softness, ease of processing, elasticity, and non-corrosive nature towards contact surfaces. They are widely used in fields such as automotive, mechanical equipment, aerospace, and medical devices to ensure the sealing integrity of products/equipment.

Below, Dr. Atometrics will introduce a precision inspection case study for rubber sealing rings.

01 Overview and Classification

Rubber sealing rings are annular covers composed of one or several parts. They are fixed onto a bearing ring or washer and contact another ring or washer or form a narrow labyrinth gap, preventing lubricant leakage and the ingress of foreign objects.

Depending on their shape and material, rubber sealing rings can be classified into various types. Each type has specific requirements regarding shape, material, and dimensions to adapt to different working environments and pressures.

· By Shape: O-rings, Y-rings, V-rings, Hole-type YX rings, etc.

· By Material: Silicone rubber, Fluorocarbon rubber (FKM), Poly Tetra Fluoro Ethylene (PTFE), Nitrile rubber (NBR), Metal rubber, etc.

02 Key Factors Affecting Sealing Performance

The important factors affecting rubber sealing rings are as follows:

· Dimensions: The accuracy of a sealing ring's dimensions directly affects its sealing performance and service life. Dimensions that are too large or too small can lead to poor sealing or even damage the equipment.

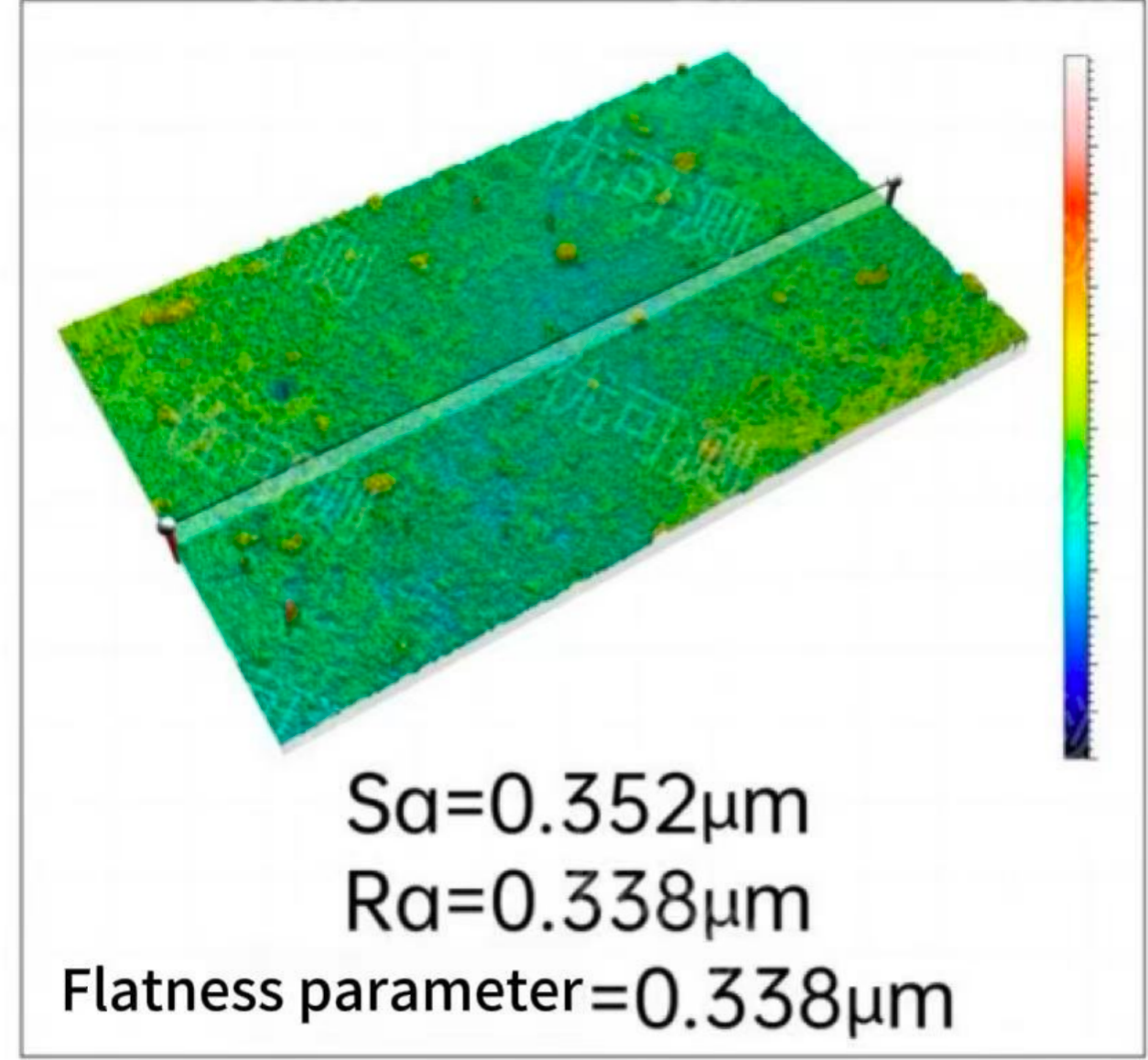

· Surface Roughness: The surface roughness of a sealing ring directly impacts its sealing effectiveness and lifespan. If the surface is too rough or too smooth, it can result in inadequate sealing, prone to leakage, leading to material loss and safety hazards.

· Flatness: The flatness of a sealing ring refers to the deviation between its surface and an ideal plane. It directly affects the degree of contact between the sealing ring and the sealing surface, as well as the sealing effect. If the flatness is substandard, it may cause poor sealing, resulting in liquid or gas leakage, and even affect the safe operation of the equipment.

03 Application Examples

[Atometrics White Light Interferometer AM Series]

Flatness measurement, surface roughness measurement, and surface 3D profile of rubber sealing rings:

[Atometrics One-Touch Image Measurement System FM Series]

Rapid batch measurement of planar dimensions such as inner/outer diameter and circumference of rubber sealing rings to screen out defective products: