With the development of modern industry, welding technology plays an increasingly important role in manufacturing. However, weld seam quality has always been a key factor restricting product quality and production efficiency. Weld seam inspection is a crucial part of welding structure quality management, affecting the success of the entire structure and even the entire project.

Next, Dr. Atometrics will introduce Atometrics's exploration in the field of weld seam inspection and related application cases. If you also have needs or challenges in weld seam inspection, please see the solutions presented by Atometrics!

Significance and Role of Weld Seam Inspection

The purposes of inspecting welds are, firstly, to ensure the integrity, safety, and usability of the welded structure, and secondly, to utilize the inspection results for controlling weld position, weld line position, weld bead height, and for weld seam tracking control.

Therefore, weld seam inspection is of great significance in ensuring product quality and improving production efficiency. Excellent welding structure quality management can not only increase output efficiency but also significantly reduce customer complaint rates to a certain extent, ensuring product quality and safety performance.

Industry Application Fields of Weld Seam Inspection

Weld seam inspection involves many industrial sectors. In the energy sector, inspecting the welds of energy transport pipelines and equipment requires weld seam inspection to ensure pipeline operational reliability, safeguard the safety of oil and gas resource transportation, and protect national economic interests from loss.

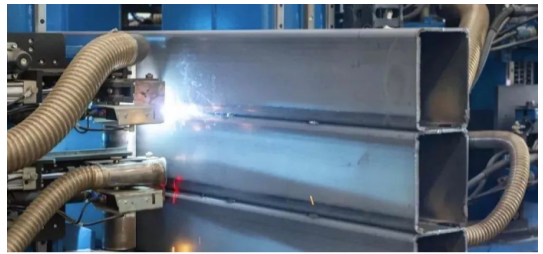

In the manufacturing industry, sectors requiring weld seam inspection include machinery manufacturing, automotive, bridges, construction, and shipbuilding. For example, in automotive manufacturing, weld seam quality directly affects vehicle safety performance; in shipbuilding, weld seam quality significantly impacts the structural strength and safety performance of ships; in bridge engineering, the quality of steel structure welds directly affects the safety and service life of the bridge.

Welding quality inspection is also essential in steel structure buildings, boiler manufacturing, and pipeline engineering within the construction industry. For instance, in steel structure engineering, weld seam quality affects material safety, stability, and mechanical properties; boiler manufacturing engineering also requires weld seam inspection to ensure the structural stability of metal components and the operational safety of the boiler.

Classification and Pros/Cons of Weld Seam Inspection Methods

1. Visual Testing (VT)

Advantages: Simple operation, no expensive equipment needed; can quickly inspect the appearance quality of welds.

Disadvantages: Highly influenced by operator experience, subjective; cannot detect internal weld defects.

2. Magnetic Particle Testing (MT)

Advantages: Can detect surface defects on welds; simple operation, low requirement for operator experience and skill.

Disadvantages: Cannot detect internal weld defects; requires high surface preparation of the weld.

3. Penetrant Testing (PT)

Advantages: Non-destructive testing, does not damage the test object; wide detection range, applicable to metals, non-metals, and composite materials; simple operation, low requirement for operator experience and skill.

Disadvantages: Detection effect is influenced by penetrant, environmental conditions, defect shape, and material surface roughness.

4. Eddy Current Testing (ET)

Advantages: Can detect weld defects; non-destructive testing, minimal impact on weld quality.

Disadvantages: Affected by weld surface condition (oxidation, dirt, etc.) impacting accuracy; affected by inspection distance, excessive distance may lead to inaccurate results; affected by material conductivity, has certain requirements for the electrical conductivity of the test material.

5. Ultrasonic Testing (UT)

Advantages: Can detect weld defects; non-destructive testing, minimal impact on weld quality.

Disadvantages: High skill requirement for operators; requires high surface cleanliness of the weld.

6. Radiographic Testing (RT)

Advantages: Can detect weld defects; non-destructive testing, minimal impact on weld quality.

Disadvantages: High equipment cost; high skill requirement for operators; the operation process may produce radiation.

7. Line Laser Measurement Instrument Testing

Advantages: Can detect weld defects; non-destructive testing, minimal impact on weld quality; high measurement accuracy, up to micron level; real-time measurement capability, providing real-time data support for weld quality inspection; enables automated inspection.

Disadvantages: Equipment involves certain costs.

In summary, the Line Laser Measurement Instrument incorporates all the advantages of other methods and compensates for their shortcomings. Therefore, its application in weld seam inspection across various industries is becoming increasingly widespread.

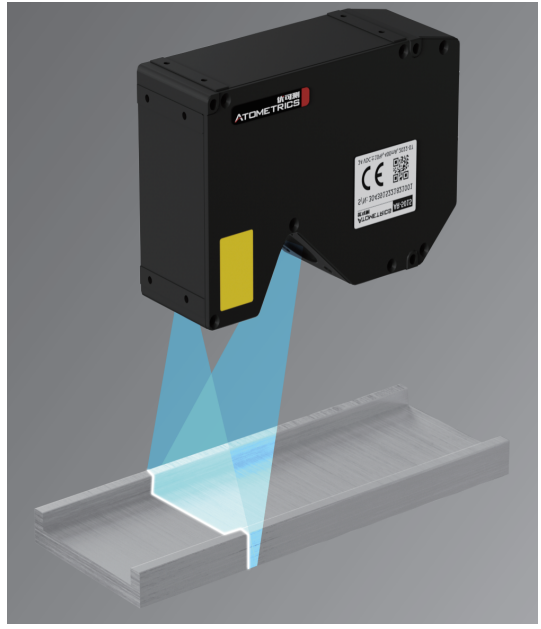

Principle of Atometrics 3D Line Laser Measuring Instrument AR-7000 Series

The Atometrics 3D Line Laser Measuring Instrument AR-7000 series is a non-contact surface measurement device based on laser technology. It utilizes a high-brightness, long-life light source to emit a laser line of a specific wavelength. When this laser line strikes the measured sample, reflected light is formed. Only light of the corresponding wavelength can pass through the ultra-high-definition optical glass and be received by the instrument. The instrument receives the reflected optical signal, and after data processing, obtains point cloud data of the sample, thereby enabling inspection of the sample's surface profile, 3D topography, flatness, weld seam quality, etc.

Three Major Advantages of Atometrics 3D Line Laser Measuring Instrument AR-7000 Series

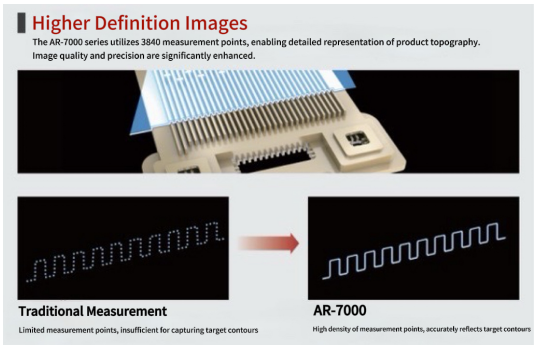

1. Employs high-precision measurement with 3840 points, repeatability accuracy up to 0.4μm, capable of finely presenting the 3D topography of the product, significantly improving image quality and detail level.

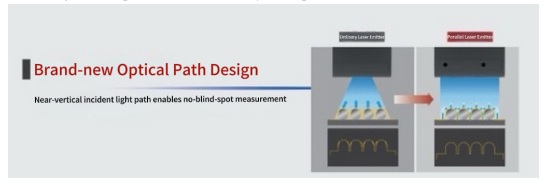

2. A novel optical path design allows for nearly vertical blind-zone-free measurement, enhancing the completeness and accuracy of inspection results.

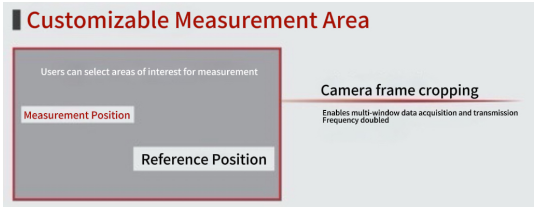

3. Users can customize the selection of areas to be measured. The AR-7000 series camera allows for frame splitting, enabling multi-window data acquisition and transmission, with frequency increased by 2 times.

Application Case of Atometrics 3D Line Laser Measuring Instrument AR-7000 Series

Case Background

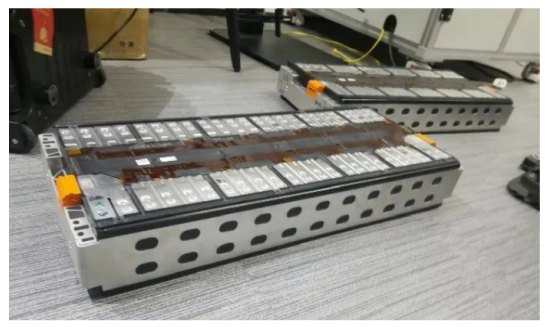

A new energy technology company specializing in lithium batteries, battery modules, BMS, and energy storage batteries wanted to ensure outgoing product quality, enhance product safety performance, and reduce customer complaint rates. They hoped to inspect the side seam welds of Busbar battery modules. The inspection items included weld breaks, gaps, collapses, spatter holes, narrow welds, protrusions, and mismatch, aiming to screen out defective welds.

Actual photo of Busbar battery module

To introduce cost-effective measurement equipment for weld seam inspection and better improve product quality, this company sought help from Atometrics, a domestic independent brand focusing on high-precision measurement.

Solution

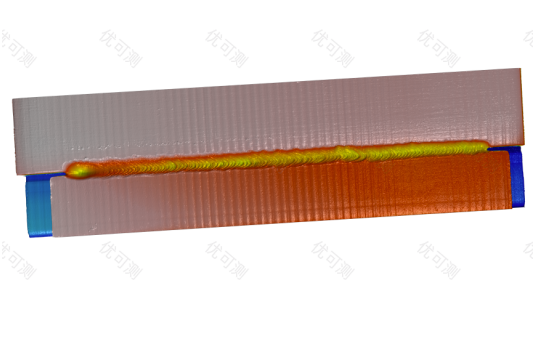

1. Weld Break Detection: Requirement: NG if the length of the broken weld part exceeds 1mm.

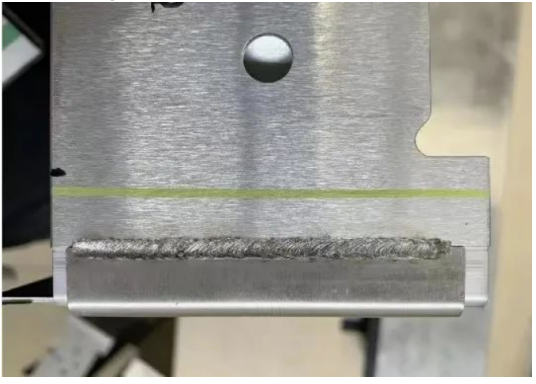

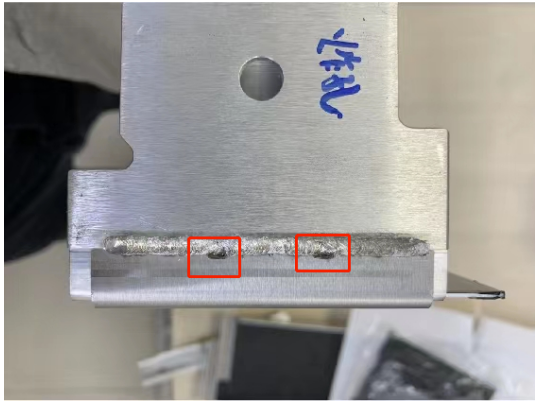

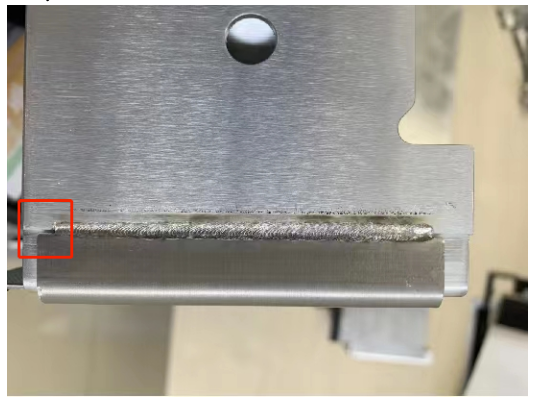

Actual photo of weld break section

Atometrics Solution: Process the height point cloud data, use the continuous contour tool to measure the step at multiple positions.

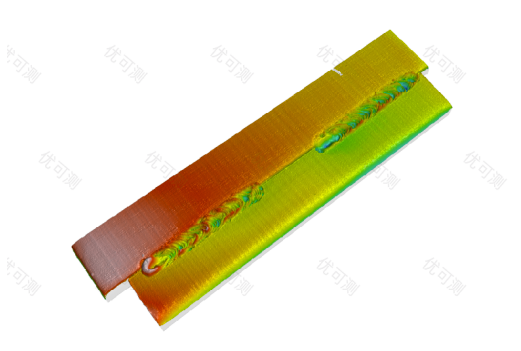

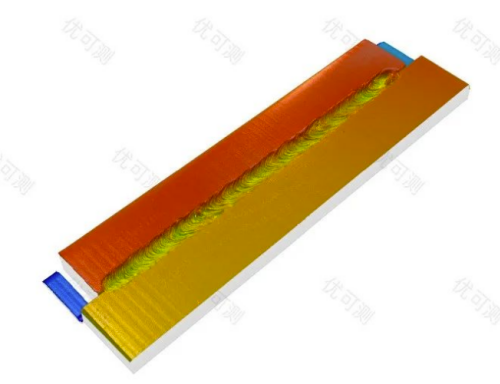

AR-7000 scanned image of weld break

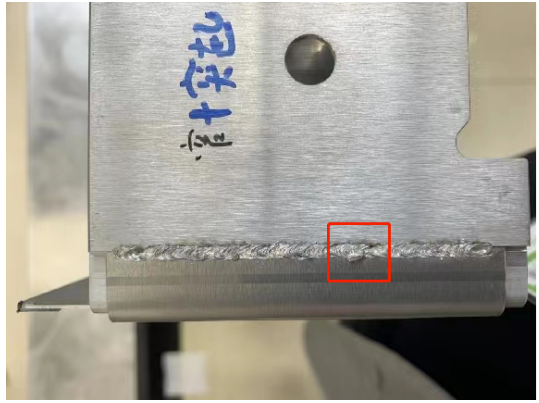

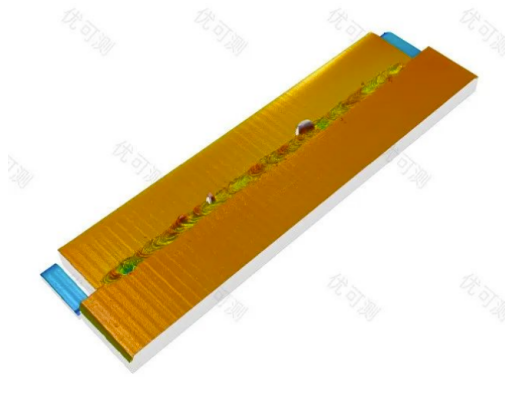

2. Collapse Detection: Requirement: NG if the length of the collapsed part exceeds 0.5mm and the depth exceeds 0.5mm.

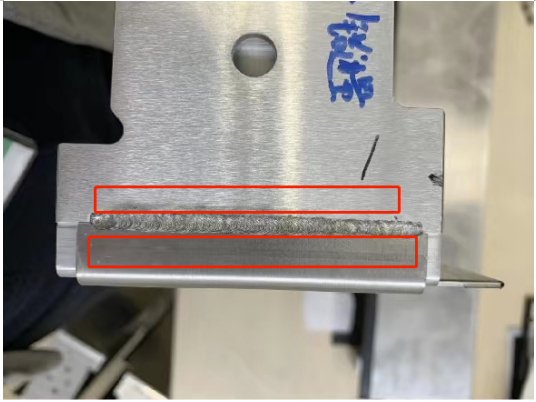

Actual photo of weld collapse section

Atometrics Solution: Process the height image, measure the weld collapse using the height detection tool.

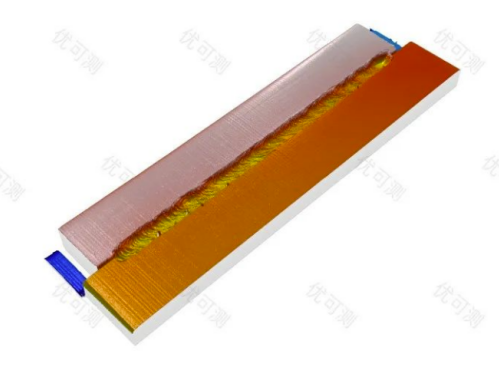

AR-7000 scanned image of weld collapse

3. Spatter Point Detection: Requirement: NG if the diameter of the spatter point exceeds 0.2mm.

Actual photo of weld spatter point section

Atometrics Solution: Process the height image and grayscale image, measure the weld spatter point using depth and length detection tools.

AR-7000 scanned image of weld spatter point

4. Mismatch/Step Height Detection: Requirement: NG if the height difference between the two ends exceeds the standard value by more than 0.1mm.

Actual photo of weld mismatch section

Atometrics Solution: Process the grayscale image, measure the gap using the width detection tool.

AR-7000 scanned image of weld mismatch

5. Gap Width Detection: Requirement: NG if the gap width exceeds the standard value by more than 0.1mm.

Actual photo of weld gap section

Atometrics Solution: Process the grayscale image, measure the gap using the width detection tool.

AR-7000 scanned image of weld gap

6. Excessive Weld Width / Protrusion Detection: Requirement: NG for products with excessively narrow gaps or protrusions.

Actual photo of weld protrusion section

Atometrics Solution: Process the height image and grayscale image, measure the weld gap and protrusion using width and height detection tools.

AR-7000 scanned image of weld protrusion

The Atometrics 3D Line Laser Measuring Instrument AR-7000 series possesses professional flaw detection algorithms that meet various weld quality inspection needs, clearly and finely reflecting weld quality. The operation interface can be customized to display images, data, statistics, etc.

Atometrics can provide customization for specific customer measurement requirements and also possesses certain script editing development support capabilities, offering after-sales debugging and software development assistance services.