In recent years, with the development of the meat processing industry and the transformation and upgrading of traditional meat processing operations, more and meat processing plants are shifting from traditional manual cutting to intelligent meat cutting equipment, leading to increasing demand for intelligent cutting machines.

I. Scenarios Requiring Meat Cutting

China's meat industry chain is divided into upstream, midstream, and downstream sectors. The upstream primarily consists of farms, the midstream mainly includes slaughterhouses and processing plants, and the downstream primarily comprises wholesalers, retailers, and food processing plants. Among these, slaughterhouses, processing plants, retailers, and food processing plants are the main entities that need to cut and portion meat.

1. Slaughterhouses and Processing Plants

In slaughterhouses and processing plants, meat is typically processed differently based on various customer requirements. Some only require the meat to be segmented by part, usually performed by professional butchers. Others require specific cuts of raw meat to be portioned into pieces of a certain weight, where intelligent portioning machines can be used for efficient and precise cutting.

2. Retail

In the retail sector, meat is generally sold by part. In some premium supermarkets, there is also a requirement for meat from the same part to be cut into pieces of the same thickness or weight before packaging and sale, such as thinly sliced fatty beef rolls, lamb chops, selected pork ribs, etc.

3. Food Processing Plants

In food processing plants, depending on the processing requirements of different products, meat is generally cut into pieces of a specific weight or thickness before subsequent processing, such as for snacks like beef jerky or chicken breast.

II. Methods for Cutting Meat

Currently, meat cutting and processing methods are mainly divided into two categories: manual cutting and machine portioning.

1. Manual Cutting: Hiring professional butchers for manual segmentation and portioning. An experienced butcher can debone and segment a whole pig weighing over 50 kg in about 6 minutes.

2. Machine Portioning: There are various types of meat portioning machines available on the market, such as frozen meat cutters, meat slicers, bone cutters, de-skinners, etc.

III. Advantages of Unmanned Intelligent Cutting

1. Better Meat Quality: Compared to manual cutting, intelligent cutters offer precise cuts and clean separation in a single stroke, eliminating the need for repeated sawing. This effectively preserves the appearance and integrity of the meat, thereby reducing customer complaints.

2. Accurate Portioning: Depending on different cutting requirements, it ensures consistent shape/thickness/weight for each portioned product, reducing raw material waste, improving utilization rate, and thus saving on material costs.

3. Reduced Labor Costs and Increased Output Efficiency: Unmanned operation can eliminate the need for multiple personnel, requiring only a few operators for the intelligent cutting machines. Furthermore, compared to manual cutting, machine cutting is faster and more accurate, thereby enhancing output efficiency.

4. Clean, Hygienic, and Contamination-Free: Utilizing unmanned operation helps isolate contamination sources from the outset, ensuring a clean, hygienic, and germ-free production environment.

IV. 3D Line Laser Measuring Instrument Meat Topography, Enabling Precise Cutting with the Portioning Machine

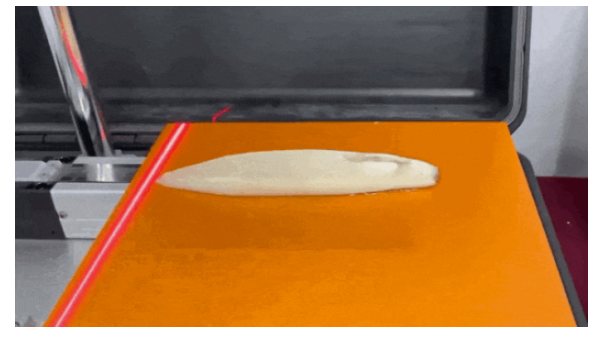

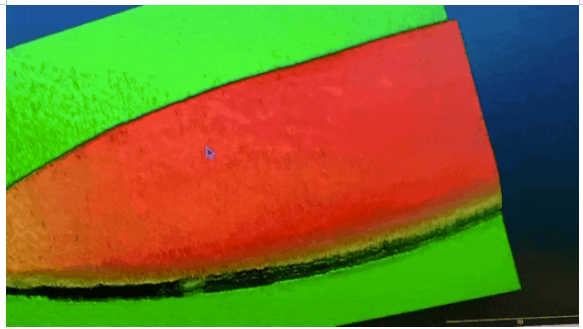

A certain university's College of Agriculture, responding to the "Intelligent Meat Processing" project and aiming to research intelligent meat processing technology, sought to develop an intelligent portioning machine. This required topography analysis of the meat to be cut. The topography information would be transmitted to the cutter to guide precise cutting with the tool, thereby achieving intelligent meat processing. Upon receiving the inspection requirement, Atometrics used the 3D Line Laser Measuring Instrument AR-7250 to perform topography inspection on sample pork:

After receiving the inspection results and proposal, the university professors praised the measurement accuracy and precision of the Line Laser Measuring Instrument AR-7250, and also expressed great appreciation for Atometrics's contribution to the development of intelligent meat processing. Atometrics is consistently committed to supporting technological iteration and upgrade across various industries. Therefore, we are honored to participate in this university's scientific research project on modern meat processing technology. Atometrics believes: Intelligent Technology Leads the Future.

The Atometrics 3D Line Laser Measuring Instrument AR-7000 Series is a non-contact surface measurement device based on laser technology. It utilizes a high-brightness, long-life light source to project a laser line of a specific wavelength. When this laser line strikes the measured sample, reflected light is formed. Only light of the corresponding wavelength can pass through the ultra-high-definition transparent optical glass and be received by the instrument. The instrument receives this reflected optical signal, and after data processing, obtains point cloud data of the sample, enabling inspection of contour, defects, flatness, evenness, height difference, etc. The Atometrics 3D Line Laser Measuring Instrument AR-7000 Series employs 3,840 points per profile, allowing for detailed representation of product topography and significantly improving image quality and fineness.