Since its establishment, Atometrics has consistently adhered to the philosophy of "Heartfelt Inspection," and has been pleased to assist students and faculty from universities, research institutes, and laboratories in their academic research. We are committed to supporting the development of 3D printing technology and fostering industry innovation, thereby driving the vigorous growth of scientific research in China.

With the continuous advancement of science and technology, the application scenarios for 3D printing technology are exceedingly broad, holding significant value in diverse fields such as optical lenses, biomedicine, energy, environmental protection, and electronics. The application and development of 3D printing technology are extensive, spanning many different sectors. In manufacturing, it is used for rapid prototyping, production of custom components, and fabrication of complex structures. The medical field utilizes 3D printing to manufacture prosthetics, medical devices, and models of human tissues. The education sector also employs 3D printing technology to help students grasp abstract concepts and engage in hands-on practice. Furthermore, industries like aerospace, architecture, and art are actively exploring and applying 3D printing technology. In summary, the applications of 3D printing technology continue to expand and deepen, bringing numerous opportunities for innovation and development across various fields.

Researchers from institutions including the Chinese Academy of Sciences, Shenzhen University, Jiangnan University, and the Guangdong-Hong Kong Joint Research Center for Optical Fiber Sensors have conducted in-depth studies on 3D printed lens technology using the Atometrics White Light Interferometer AM Series. They performed detection and verification on experimental samples for aspects such as surface micro 3D topography, curvature radius, and surface profile. Below are shares of some selected research papers:

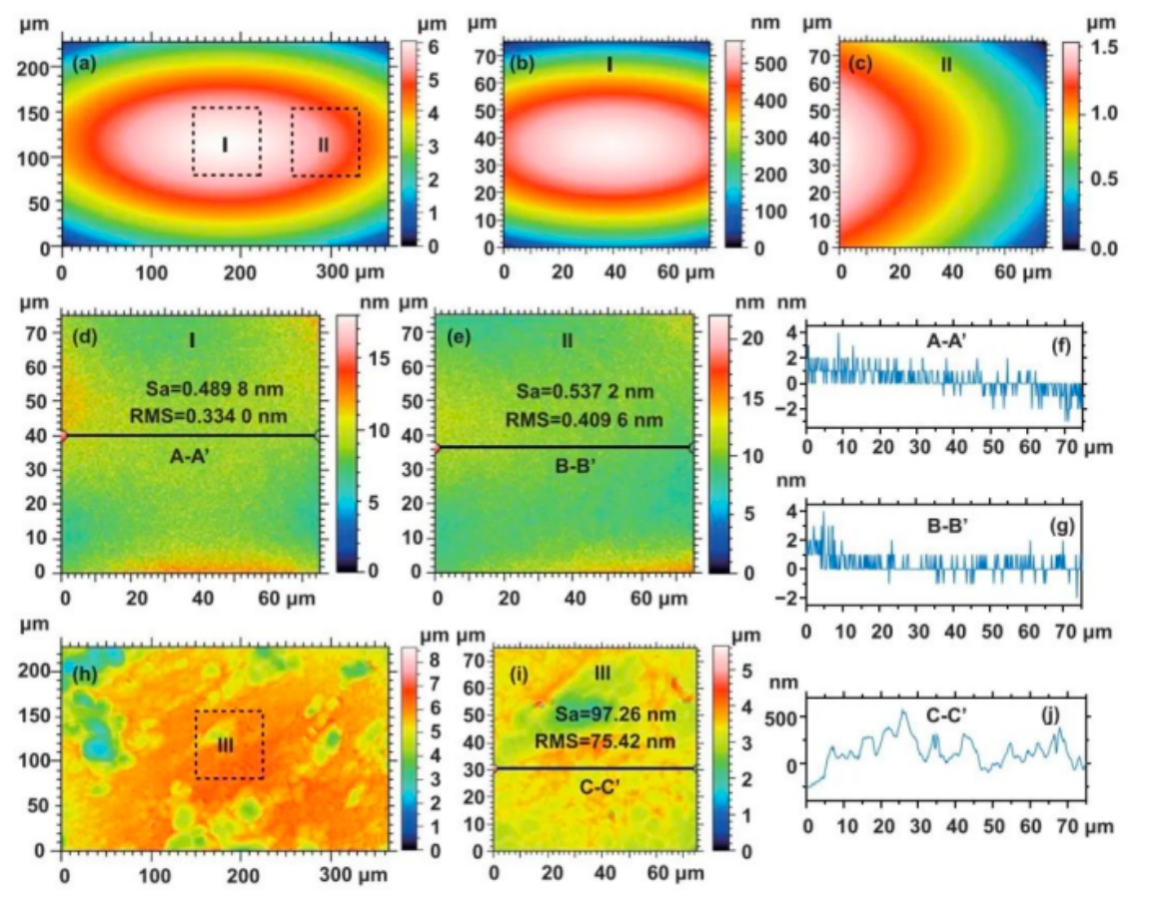

"Ultra-fast 3D printing of assembly-free complex optics with sub-nanometer surface quality at mesoscale"

(CAS Zone 1) IF: 14.7

Paper Link:

https://doi.org/10.1088/2631-7990/acdb0d

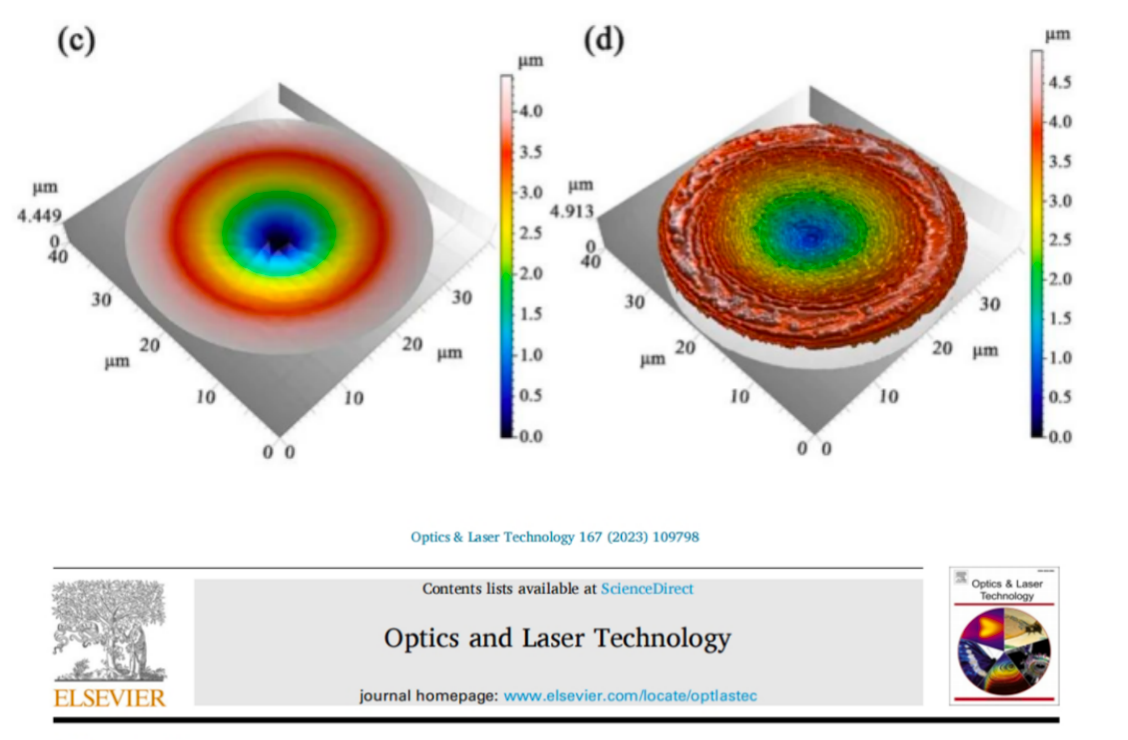

"Doughnut beam shaping based on a 3D nanoprinted microlens on fiber tip"

(CAS Zone 2)

Paper Link:

https://doi.org/10.1016/j.optlastec.2023.109798

---

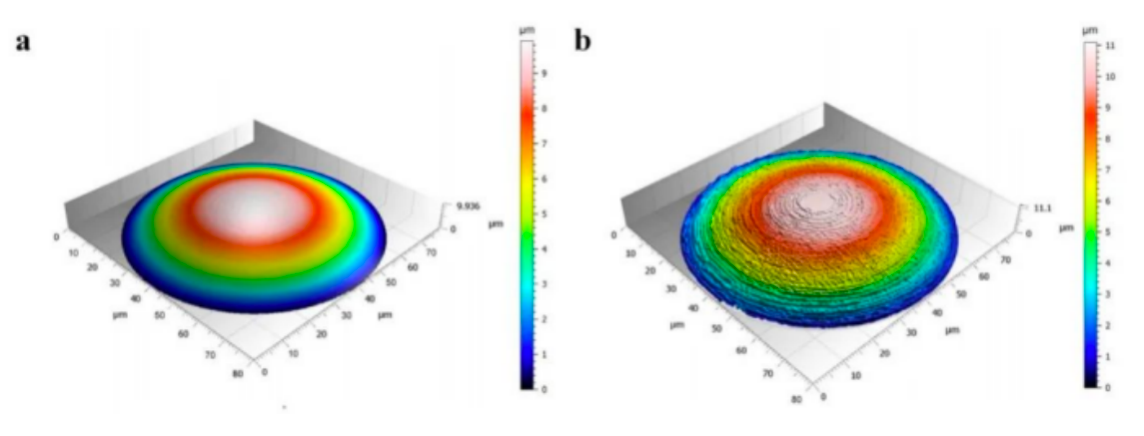

"Femtosecond laser 3D printed micro objective lens for ultrathin fiber endoscope"

(CAS Zone 3)

Paper Link:

https://doi.org/10.1016/j.fmre.2022.05.026

Since its establishment, Atometrics has consistently upheld the philosophy of "Heartfelt Inspection" and has been pleased to assist students and faculty from universities, research institutes, and laboratories in their academic research. We are committed to supporting the development of various technological disciplines and fostering industry innovation, thereby driving the vigorous growth of scientific research in China.

If your experiment or research project requires high-precision detection and verification for parameters such as surface roughness measurement / 3D topography / film thickness / step height / surface profile PV (Peak-to-Valley) / blind holes / curvature radius, etc., please feel free to contact Atometrics at any time!